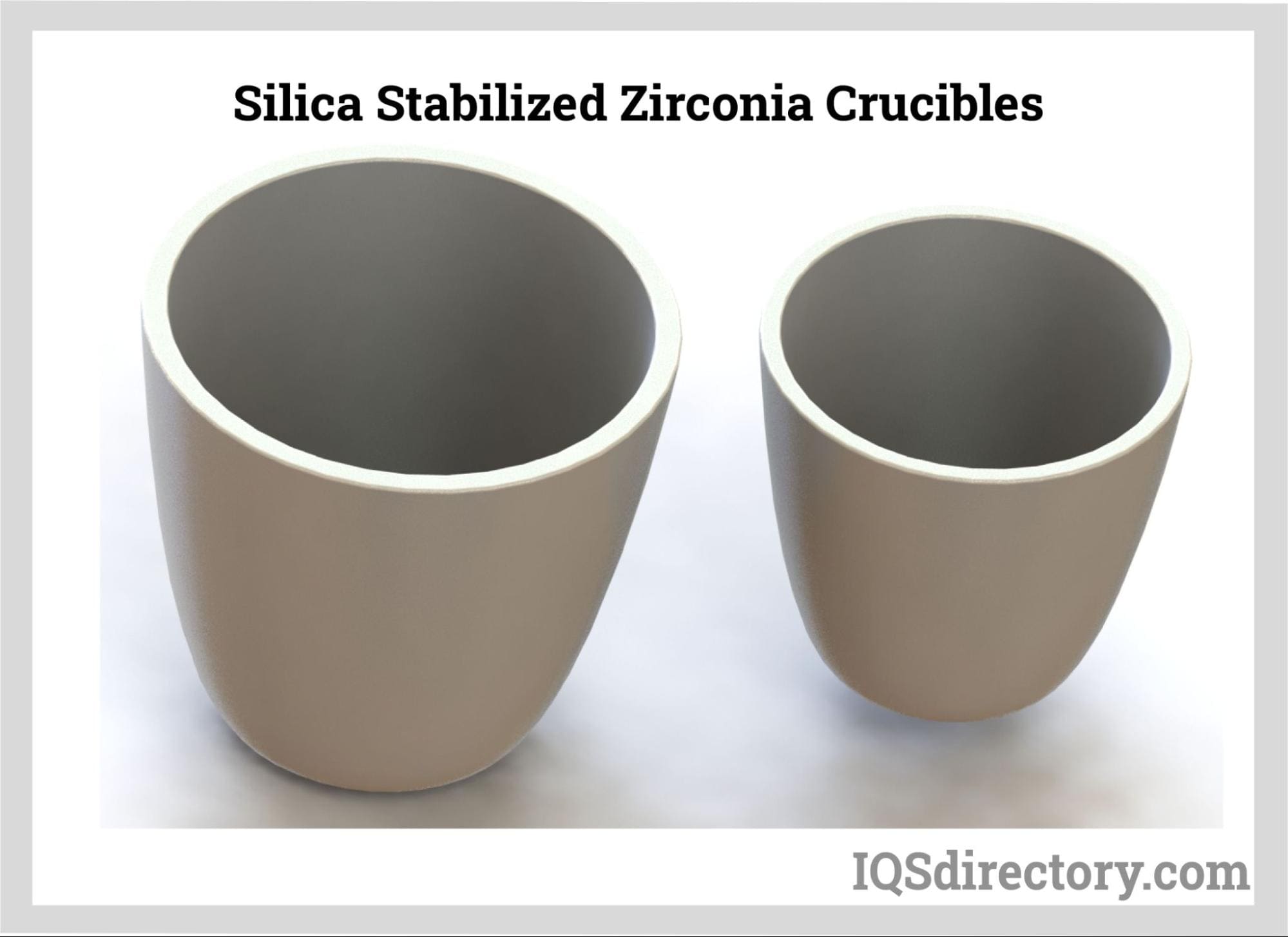

At temperatures above 1,900 °C, zirconium oxide crucibles produce cleaner melts. In addition, they provide heat-up and cool-down schedules that keep foundries active and are designed to melt super alloys and precious metals. Read More…

As a manufacturer and stocking distributor of industrial and technical ceramics, LSP carries the most diversified inventory of ceramic tubes, spacers, bushings, etc. in the industry.

C-Mac International manufactures custom advanced technical ceramic solutions. Our specialties are Zirconia (MgO stabilized and Yttria stabilized), Alumina (90%, 96%, and 99.5% purity), and Tungsten Carbide (Cobalt and Nickel Binder). We also work with steatite, cordierite, silicon nitride, ceramic crucibles, and crushable ceramics. We prioritize customer needs - we have a 48-hour delivery on...

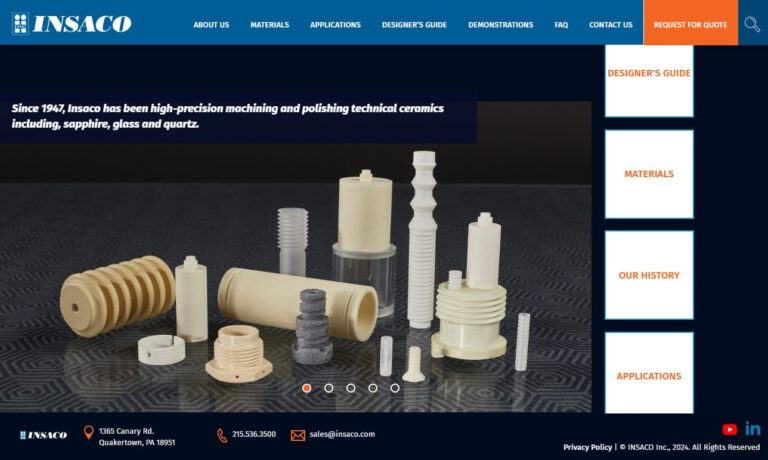

Insaco provides custom grinding and machining services to fabricate precision parts from sapphire, quartz, and most technical ceramics including alumina, zirconia, silicon carbide, silicon nitride, aluminum nitride, and others.

Applied Ceramics is a fabricator of custom-made ceramic parts designed for semiconductor, solar, fuel cell, oil drilling, nuclear, and numerous other industries. Materials include ACI-995 Alumina, Zirconia, and more. Our extensive experience with precision designs supported by our team of specialists ensures that our customers have the ideal solution to meet the needs of their application. To get ...

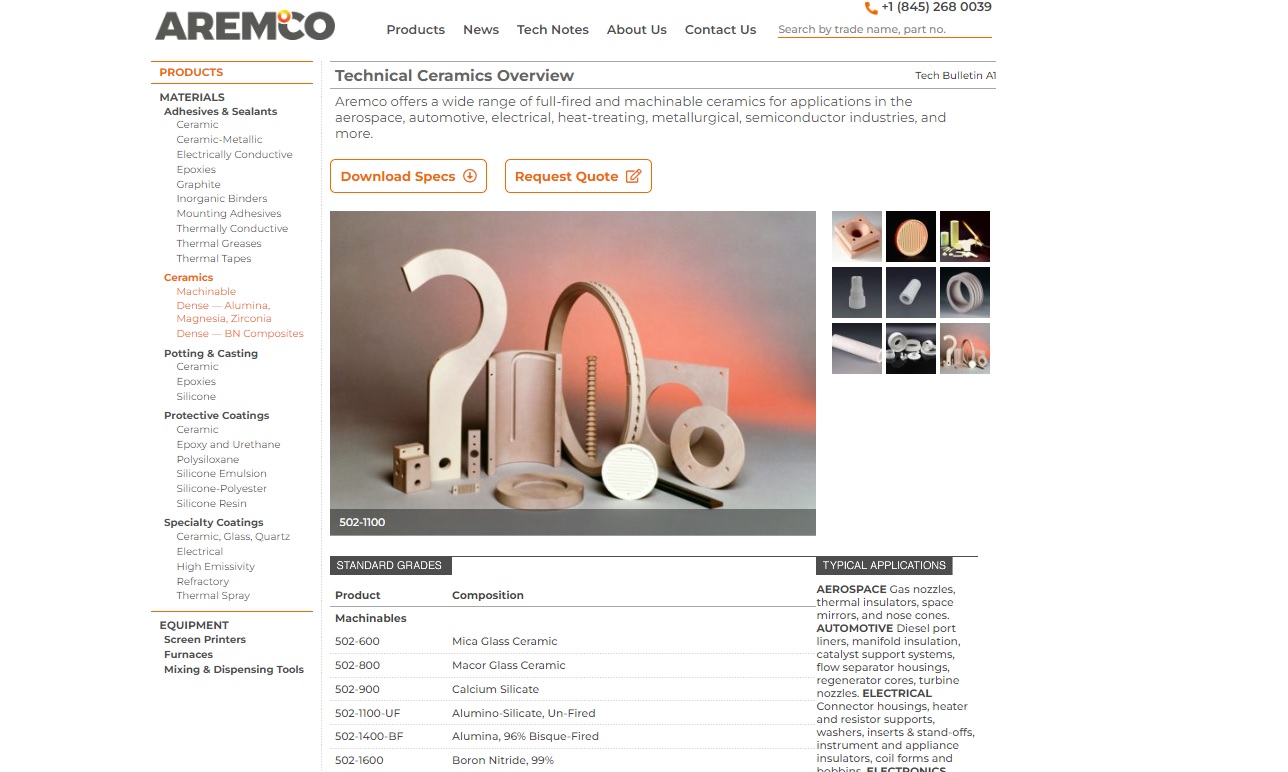

Aremco is a leader in the custom formulation of advanced industrial materials including technical ceramics. Offering many capabilities for a broad range of machinable & dense ceramic materials, Aremco serves aerospace, automotive, electrical, electronics, heat treating, metallurgical, petrochemical & plastics applications with superior finished ceramic parts. 100’s of standard industrial...

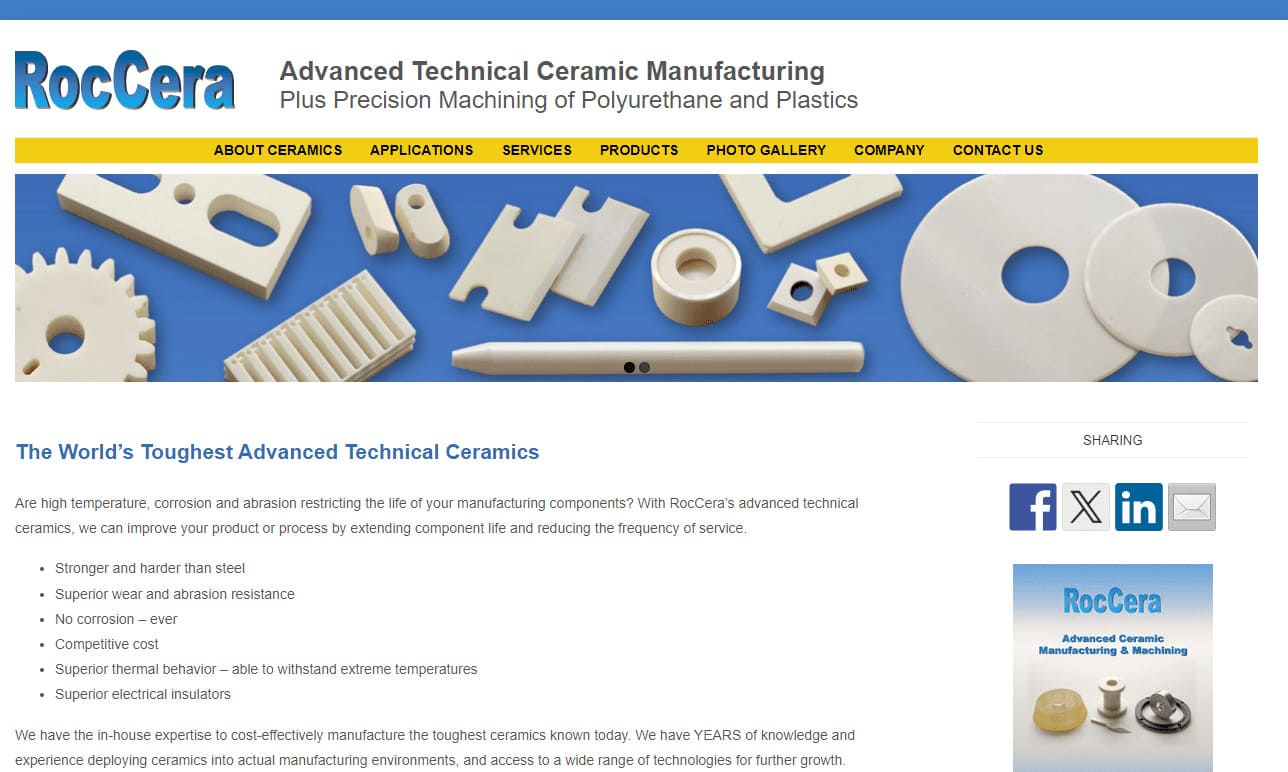

RocCera designs high-performance ceramic components. With a relentless pursuit of excellence and innovation, we have positioned ourselves as a leading provider of custom ceramic solutions catering to a diverse range of industries. Specializing in advanced technical ceramics, RocCera boasts a versatile portfolio that includes the manufacturing of ceramic components for various applications. Our...

As an ISO 9000 and QS 9000 company, CeramTec North America offers ceramic products such as ceramic insulators, ceramic cutting tools, ceramic substrates and ceramic-to-metal joints. We are one of the world's largest ceramic manufacturers that offer custom-engineered high-tech ceramics.

More Zirconia Ceramic Manufacturers

Types of Zirconia Crucibles

Calcia Stabilized Zirconia (CSZ) Crucibles

Calcia stabilized zirconia crucibles can overcome the difficulties posed by humid and rainy conditions because it is strong and resilient. It is an excellent material for generating sensors, instruments, probes, pumps, and fluid control systems due to its strong flexural and compressive strength. Furthermore, CSZ is more resistant to molecular water attack and can survive high temperatures, so it is employed when concerns about low-temperature degradation are present.

Fully-Stabilized Zirconia (FSZ) Crucibles

Yttrium, a rare earth metal that is silvery-white, ductile, and soft, stabilizes FSZ. It is utilized in high-temperature applications that require exceptional corrosion resistance, fracture toughness, and thermal shock resistance. Only oxygen ions may travel through FSZ, distinguishing it and making it useful for applications like active membranes. Zirconia changes from monoclinic to tetragonal to cubic, which increases its volume and causes fissures in the ceramic. The cubic polymorph can be stabilized and withstand a wide temperature range by adding yttrium.

Tetragonal Zirconia Polycrystalline (TZP) Crucibles

Tetragonal zirconia polycrystalline (TZP) ceramics exhibit exceptional fracture toughness and hardness at room temperature and corrosion resistance at high temperatures. They are the primary component in surgeries such as dental reconstruction and hip replacement. Fuel rod claddings in the industrial sector are coated with TZP to act as a thermal barrier. A robust, rigid material with an ideal microstructure is necessary for applications that call for the usage of TZP. TZP is similar to iron and iron-based alloys in thermal expansion coefficient. Because of its outstanding fracture toughness, it is known as ceramic steel.

Transformed, Toughened Zirconia (TTZ) Crucibles

TTZ is known as ceramic steel because it responds to stress with a strain pattern more like that of steel than a brittle ceramic material. Martensitic phase transition alters a material's stress state by raising tensile stress and acting against applied stress; it transforms and toughens zirconia ceramic.

Zirconia ceramics undergo a phase shift when tension is applied, raising the ceramic's volume and decreasing the local stress to prevent crack propagation. The procedure makes ceramic materials tougher. Ceramic knives, which are twice as hard as conventional steel knives and have ultra-sharp blades for accuracy and delicate cutting, are a typical application for TTZ.

How Zirconia Crucibles are Made

Mixing

- Mixing is a necessary step in creating the composite powder and can be done mechanically, in a multiphase solution, with a sol suspension, or with a sol-gel. The various techniques are chosen to guarantee a thorough blending of the composite powder; each has advantages.

- Mechanical mixing is the simplest to grasp, but it offers the least assurance that the components will be distributed uniformly. Most of the time, mechanical mixing results in a mixture with a high porosity, which affects the zirconia material's mechanical properties.

- Preparing a single-phase suspension with dispersed components is the initial stage in the multiphase suspension mixing process. The next step is identifying the conditions required for the particles in each phase to scatter uniformly. Finally, the typical flocculation conditions create uniformly mixed power. The flocculant absorbs the submicron flocs that result from mixing the suspended materials and fills the space between them.

- Sol Suspension: Nano sol is a heterogeneous mixture that allows for the mixing of suspensions. The sol can be heated or agitated if the solid concentration is high to make high-mixed nanocomposite ceramics

- Sol-gel is a method that creates solid materials from very small molecules by converting monomers into a colloidal solution, which serves as the gel's base. As a result, it generates a thoroughly-blended nanopowder.

Grinding and Packing

The mixture is blended with a stabilizer to create a ball, which is then squeezed between 60 MPa and 100 MPa under a small binder. Next, the zirconia oxide powder is made through compression, bringing the stabilizer particles into proximity.

Sintering Method

Sintering, which raises the stabilized zirconia powder to temperatures well over 1,000o C, is crucial for the quality and proper processing of zirconia ceramics. There are various techniques to sinter materials; the most popular methods include electric, high pressure, activation, and hot press.

Machining of Sintered Ceramics

Sintered zirconia ceramics must be machined to prepare the solidified material for various applications. Zirconia ceramics provide difficulties when machining mostly because of their remarkable hardness, which is relatively comparable to steel.

Uses of Zirconia Ceramics

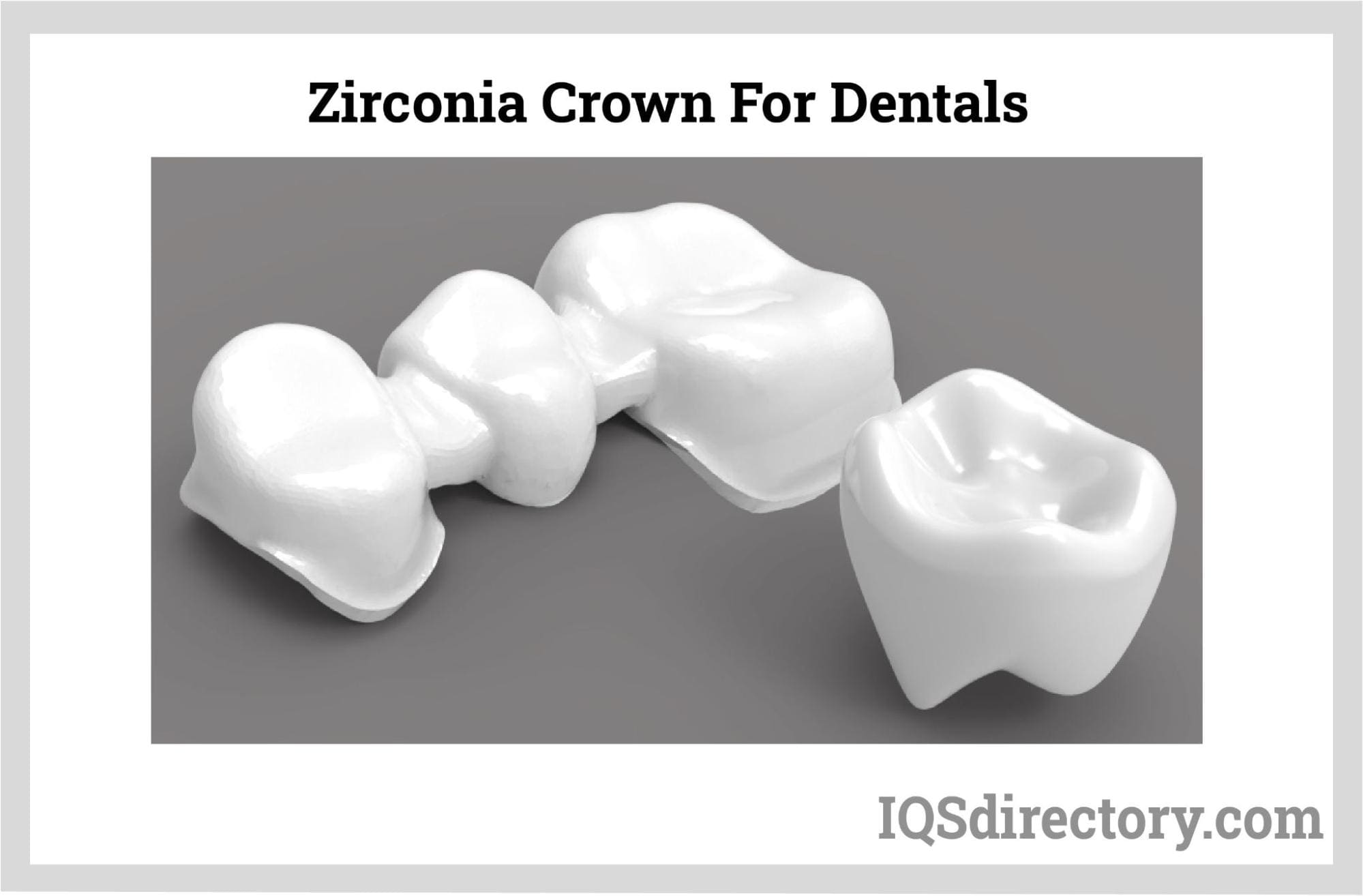

Uses of Zirconia Ceramic in Dentistry

Tetragonal zirconia polycrystalline, magnesium stabilized, and ZTA are the three types of zirconia ceramic utilized in dentistry. Zirconia ceramics possess the qualities needed to function well for tooth restoration. In addition, since it does not induce allergic reactions, it is significantly superior to the metal dental materials of the middle of the 20th century in terms of aesthetics and strength. Zirconia is used for posts, crowns, bridges, and implants in dentistry.

Uses of Zirconia in Joints

Dense zirconia ceramics are employed for replacement joints, particularly for surfaces that can withstand wear. Zirconia ceramics may be polished to an exceedingly smooth finish and have mechanical advantages over metal alloys. As a bearing surface, the material's capacity to resist scratches is quite advantageous. Zirconia ceramic cutting blades work well for cutting membrane materials, including paper, aluminum, and steel.

Choosing the Proper Zirconia Crucibles Company

To make sure you have the most productive outcome when purchasing Zirconia Crucibles from a Zirconia Crucibles Supplier, it is important to compare at least 6 Suppliers using our list of Zirconia Crucibles companies. Each Zirconia Crucibles Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Zirconia Crucibles business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Zirconia Crucibles businesses with the same message.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services