Ceramic manufacturing is the process used to sinter and fabricate ceramic materials into non-metal parts. The term “ceramics” refers to a wide range of products and materials used for an equally wide variety of applications, from commercial uses to the aerospace industry. They may come in the form of powdered composites or semi-liquid inorganic materials. Read More…

As a manufacturer and stocking distributor of industrial and technical ceramics, LSP carries the most diversified inventory of ceramic tubes, spacers, bushings, etc. in the industry.

C-Mac International manufactures custom advanced technical ceramic solutions. Our specialties are Zirconia (MgO stabilized and Yttria stabilized), Alumina (90%, 96%, and 99.5% purity), and Tungsten Carbide (Cobalt and Nickel Binder). We also work with steatite, cordierite, silicon nitride, ceramic crucibles, and crushable ceramics. We prioritize customer needs - we have a 48-hour delivery on...

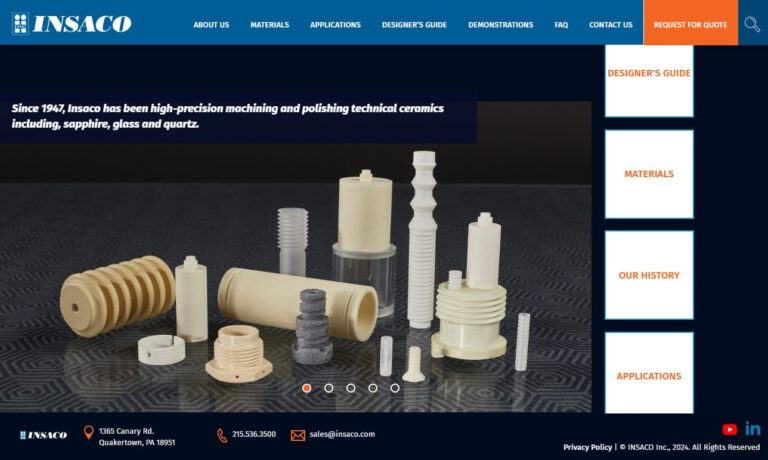

Insaco provides custom grinding and machining services to fabricate precision parts from sapphire, quartz, and most technical ceramics including alumina, zirconia, silicon carbide, silicon nitride, aluminum nitride, and others.

Applied Ceramics is a fabricator of custom-made ceramic parts designed for semiconductor, solar, fuel cell, oil drilling, nuclear, and numerous other industries. Materials include ACI-995 Alumina, Zirconia, and more. Our extensive experience with precision designs supported by our team of specialists ensures that our customers have the ideal solution to meet the needs of their application. To get ...

Aremco is a leader in the custom formulation of advanced industrial materials including technical ceramics. Offering many capabilities for a broad range of machinable & dense ceramic materials, Aremco serves aerospace, automotive, electrical, electronics, heat treating, metallurgical, petrochemical & plastics applications with superior finished ceramic parts. 100’s of standard industrial...

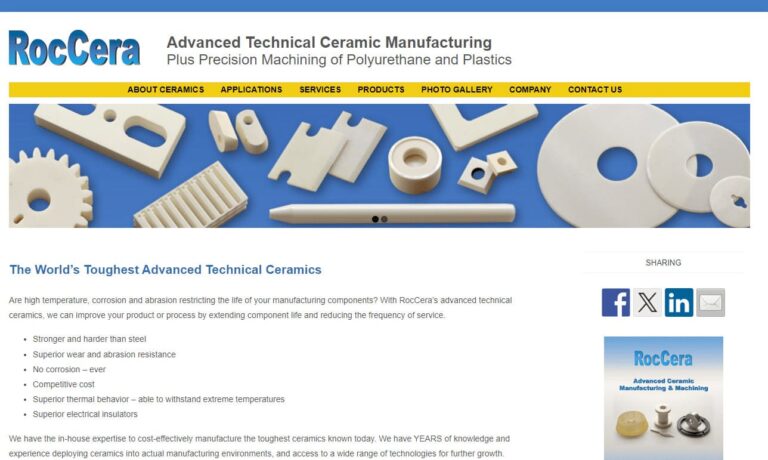

RocCera designs high-performance ceramic components. With a relentless pursuit of excellence and innovation, we have positioned ourselves as a leading provider of custom ceramic solutions catering to a diverse range of industries. Specializing in advanced technical ceramics, RocCera boasts a versatile portfolio that includes the manufacturing of ceramic components for various applications. Our...

As an ISO 9000 and QS 9000 company, CeramTec North America offers ceramic products such as ceramic insulators, ceramic cutting tools, ceramic substrates and ceramic-to-metal joints. We are one of the world's largest ceramic manufacturers that offer custom-engineered high-tech ceramics.

More Ceramic Manufacturing Companies

What is Ceramic Machining?

Ceramic machining involves transforming ceramic materials into finished products through processes such as mixing, forming, firing, and finishing. All ceramics share common characteristics, including high-temperature resistance, wear resistance, hardness, and a crystalline structure.

Ceramic Applications

Ceramic manufacturing is crucial for producing industrial products used in high-impact applications across military, aerospace, construction, automotive, refractory, power generation, industrial, chemical, and food processing industries. These ceramic products improve manufacturing process yields and provide support for machines and machine parts in these sectors.

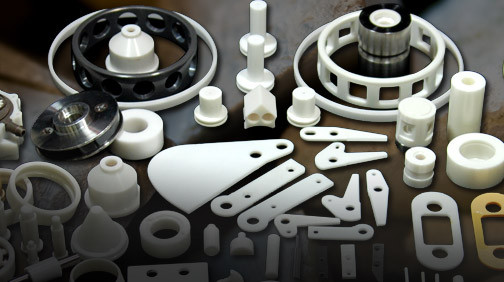

Products Produced from Ceramic Manufacturing

Ceramic products can be classified into four primary categories: structural ceramics (including bricks and tiles), refractories (such as kiln linings and crucibles), whitewares (like bone china and decorative pottery), and technical ceramics (also known as engineering or advanced ceramics).

Advanced ceramics are high-performance materials used in nuclear power, aerospace, biomedical, defense, military, and automotive industries due to their superior insulation, heat resistance, and durability. They are essential in applications like bone and tooth replacements, prosthetic limbs, blood sugar sensors, and protective body armor for soldiers. Additionally, ceramic parts and magnets enhance the performance of electric motors by withstanding engine heat.

Ceramics also include electrical ceramics, such as insulators, magnets, capacitors, and superconductors, and ceramic coatings that reduce chemical corrosion and surface temperatures of engine components. Chemical and environmental ceramics serve as fibers, membranes, and catalysts to absorb toxins, reduce pollution, and aid in water purification. Industrial ceramic products include bearings, balls, insulators, and rods.

History of Ceramics

Ceramics have been used for decorative and functional purposes for millennia. Egyptians used ceramic bricks for home decoration as early as the 4th millennium BC, and ceramic tiles adorned the Ishtar Gate of Babylon. Clay is the oldest ceramic material. However, industrial ceramics emerged in the 18th century. In 1709, Abraham Darby improved the smelting process by combining coke with clay, marking the first recorded use of ceramic engineering. About fifty years later, Josiah Wedgwood established the first ceramics manufacturing factory in Stoke-on-Trent, England.

In 1880, Pierre and Jacques Curie discovered piezoelectricity, paving the way for electroceramics, or piezoelectric ceramic manufacturing. In 1888, Austrian chemist Carl Josef Bayer developed a process for isolating aluminum from bauxite ore, significantly simplifying and reducing the cost of ceramic production—a method still in use today. In 1893, E.G. Acheson made a major contribution to ceramic manufacturing by inventing a process to create silicon carbide.

In the early 20th century, driven by the demands of World Wars I and II, ceramic manufacturers rapidly developed and refined ceramic material manufacturing processes. Concurrently, manufacturers and engineers advanced forming and fabrication techniques. These efforts resulted in the production of numerous safety equipment components and armaments, particularly during WWII.

In the past two decades, scientists, engineers, and manufacturers have developed numerous new ceramic materials and forming techniques. One notable material is hydroxyapatite, a synthetic version of a natural bone mineral, used to produce bioceramic products such as dental implants and synthetic bones. Ceramics are also essential for processes like space shuttle launches and missile cones. Japanese engineers are utilizing ceramic magnets for train levitation. Ongoing research focuses on improving ceramic molding for complex designs, achieving higher precision tolerances, and enhancing durability. The future of the ceramic industry holds promising innovations.

Ceramic Materials Process

Alumina Ceramic

Alumina ceramic materials, crafted from alumina oxide (aluminum oxide), are distinguished by their remarkable chemical stability and high ionic atomic bonding properties. Typically formed through injection molding or isostatic pressing, these ceramics provide a suite of superior characteristics. They boast exceptional strength, a hard and immaculate surface, and impressive resistance to corrosion and damage. Additionally, their electrical insulating properties make them a favored choice in ceramic applications, particularly within electrical insulation systems and semiconductor compounds.

Aluminum Nitride

Aluminum nitride, a synthetic alumina ceramic, is predominantly composed of aluminum and nitrogen, bound together by covalent bonds. Renowned for its high thermal conductivity and strong dielectric properties, it efficiently transmits electric force without conduction, maintaining electrical insulation. Even at temperatures exceeding 3632°F (2000°C), aluminum nitride remains stable and inert. This intriguing blend of properties positions it as an exceptional ceramic resource, ideally suited for applications in renewable energy, electronics, optics, and lighting.

Steatite Ceramics

Ceramic materials manufacturers produce steatite ceramics predominantly using magnesium silicate. These steatite ceramic products are renowned for their exceptional strength, durability, and superior electrical insulation properties. Thanks to these remarkable insulating capabilities, steatite ceramics are frequently employed in thermostats and are integral components in both commercial and residential electrical systems.

Zirconia Ceramics

Zirconia ceramics, derived from zirconium oxide and different than cubic zirconia, boast exceptional breakage and corrosion resistance. These properties make them indispensable for high-stress applications, including dental ceramics and automotive oxygen sensors.

Silicon Carbide Ceramics

Silicon carbide ceramics, crafted from fine silicon carbide particles through the rigorous sintering process, exhibit exceptional strength and durability. These robust materials are integral to manufacturing automotive clutches and brakes, ensuring high performance and reliability.

Silicon Nitride

Silicon nitride, primarily composed of silicon and nitrogen, provides exceptional creep resistance, superior thermal shock resistance, and stability and strength at high temperatures. Common applications include turbine blades, cutting tools, thermocouple sheaths, and welding nozzles.

Mullite Ceramics

Mullite ceramics, derived from the rare material mullite, offer unparalleled high-temperature resistance and strength. Ideal for applications demanding low thermal conductivity in low-pressure, high thermal expansion environments, these ceramics are more expensive due to the scarcity of natural mullite.

Ceramic Glass

Ceramic glass, a transparent ceramic material, is distinct from traditional glass. It withstands continuous high temperatures without distorting or breaking, making it ideal for wood-burning stoves and fireplaces with glass panels positioned within six inches of the flame.

Clay

Clay is the oldest and most fundamental ceramic material. It is not utilized in industrial ceramics but is essential in producing traditional ceramic products such as bone china, porcelain, stoneware, and earthenware.

Ceramic Process Details

The industrial ceramic manufacturing process involves several key stages: milling, batching, forming, drying, sintering, and finishing.

Milling is the stage where raw material is shaped into a small, predetermined form through sub-stages like destructing, compressing, and impacting. In the batching stage, manufacturers assemble materials according to the ceramic preparation method and produce additives. This step enhances and customizes the ceramic material’s properties. During mixing, all ceramic ingredients are combined, often by turning them into slurries with water or another liquid additive.

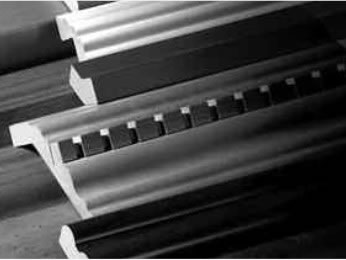

Once the base is prepared, manufacturers start fabricating ceramic products using various forming processes, including slip casting, pressing, extrusion, or injection molding. Slip casting is ideal for mass-producing sanitary ware, thin walls, and complex shapes. Pressing methods, such as hot pressing and hot isostatic pressing, are suited for advanced ceramics. Extrusion and injection molding are best for creating simpler ceramic products like pipes and tubes.

The next step is to thoroughly dry the newly formed ceramic part, ensuring the shape is solidified and ready for further processing.

During sintering, the ceramic piece, now called greenware, is placed in an extremely hot oven or kiln. This process strengthens the greenware as its oxides bond and densify, forming ionic and covalent bonds, as well as the ceramic’s crystal structure. Sintering also involves cations, and the difference in electronegativity between cations and anions determines the ionic structure.

The final touch in the ceramic manufacturing process is finishing. Manufacturers achieve this by subjecting the ceramic piece to secondary processes such as machining, glazing, cutting, grinding, or polishing.

Alumina Ceramic Production

Alumina ceramics are produced through a meticulous process that begins with the grinding of bauxite in a processing plant. This ground bauxite undergoes washing, drying, and dissolution in a mixture of caustic soda and lime, forming a slurry. The slurry is then heated in a digester to 300°F (145°C), under pressure, to dissolve aluminum compounds effectively. Once heated, the product is pressed with a 50 lbs. weight for several hours to enhance dissolution.

Subsequently, the slurry is transferred to flash tanks, where pressure and heat are reduced, facilitating further processing. In settling tanks, heavier materials such as sand and iron settle to the bottom, separating from the aluminum-rich solution. The clarified solution then passes through filters to remove fine impurities, recovering purified alumina for subsequent stages.

To further refine the alumina, the filtered solution is directed through precipitators where tiny alumina particles, acting as seeds, initiate crystallization. Alumina particles grow around these seeds and settle to the bottom of the tank, where they are filtered out to achieve purified alumina hydrate.

The next critical step involves calcination, where alumina hydrate is heated in a rotating, inclined, gas-fired kiln. This process ensures uniform heating to remove residual water and impurities, resulting in the production of high-purity alumina ceramics ready for use in various industrial applications.

Throughout this intricate production process, careful control of temperature, pressure, and filtration ensures that the final alumina ceramics meet stringent quality standards, making them suitable for diverse technological and industrial uses.

Mixing of Alumina Powder

After the refining process, the extracted powder undergoes crucial mixing with various materials, which significantly influences the quality and properties of the resulting ceramics. The mixing processes employed include spray-dried powder, aqueous slip, and ceramic dough feedstock.

Spray-Dried Powder: This method involves producing granulated powder specifically designed for both uniaxial and isostatic pressing techniques. Initially, raw powder is crushed in water, and then a binder is introduced to strengthen the material, preparing it for the pressing process.

Aqueous Slip: In this process, a slurry is created that is particularly suited for casting ceramics. The aqueous slip provides a fluid medium that facilitates the shaping and casting of ceramic components with intricate details and shapes.

Ceramic Dough Feedstock: This approach produces a clay-like material by blending water, alumina, a binder, and a plasticizer. The resulting mixture has a malleable consistency, enabling it to be shaped into desired forms before undergoing further processing steps such as drying and firing.

Each of these mixing methods plays a critical role in the preparation of alumina and other additives, ensuring that the ceramics achieve the desired grade, structural integrity, and performance characteristics required for their intended applications. These carefully controlled processes contribute to the consistency and quality of the final ceramic products used across various industrial and technological fields.

Alumina Ceramic Forming Process

In ceramic production, the process of forming the final ceramic product is crucial and involves several methods tailored to achieve specific shapes and characteristics.

Extrusion is a method where ceramic dough feedstock is subjected to pressure to deform it into desired shapes. Binders within the mixture help maintain the shape post-drying, ensuring structural integrity. Isostatic pressing utilizes isostatic pressure on sprayed powder contained within a rubber or polyurethane bag. This process can be either wet or dry: wet bag pressing suits simpler shapes, while dry bag pressing accommodates more intricate geometries.

Slip casting involves pouring an aqueous slurry into a mold, allowing water to drain and leaving a layer of ceramic powder on the mold’s inner surface as the cast thickens. Uniaxial pressing employs compression to shape alumina powder in a single axial direction using a piston or plunger, ensuring uniformity and strength in the final ceramic piece.

Electrophoretic deposition (EPD) leverages electrostatic forces to deposit ceramic particles suspended in a liquid onto a mold’s surface. Widely used in industrial processes, EPD is pivotal in ceramic production for precise coating and deposition applications. These methods each offer distinct advantages in forming ceramic products, catering to varying complexities and requirements in manufacturing processes.

Alumina Ceramic Finishing Processes

After sintering, ceramics undergo diamond grinding to enhance surface finish and correct dimensional inaccuracies. Diamond processes such as grinding, cutting, honing, lapping, and polishing are employed due to the hardness of alumina ceramics, ensuring optimal results.

Ceramic Design

During the ceramic manufacturing design phase, product designers prioritize meeting specific application requirements. They determine material selection, wall thickness, product dimensions, shaping methods, and manufacturing processes to efficiently produce customized ceramic components.

Machinery Used in Ceramic Manufacturing

Ceramic manufacturing relies extensively on various machines and tools to ensure efficient production processes. Key equipment includes ovens used for sintering, molds made from silicone or metal, extrusion machines, injection molding machines, and computer programs utilized for blueprint creation. These tools form the backbone of ceramic production systems, enabling manufacturers to tailor their processes to specific application needs.

Each component of the ceramic manufacturing system can be customized according to the requirements of the application it serves. Factors influencing these customizations typically include the desired production volume and speed, quality standards, complexity of shapes needed, and the inclusion of secondary processes. By adapting these parameters, manufacturers can optimize production efficiency and achieve precise outcomes tailored to their clients’ specifications.

Ceramic Benefits

Ceramic manufacturing offers numerous advantages to both users and the products themselves. Despite typically higher initial costs compared to traditional metals, rubbers, or polymers, ceramic parts deliver substantial long-term benefits.

These advantages include significantly enhanced performance reliability, cost-effectiveness, and superior performance in harsh environments. Ceramics are lightweight with high melting points, exceptional hardness (some surpassing titanium), good oxidation and corrosion resistance (often rivaling stainless steel). Moreover, certain ceramics exhibit superior electrical conductivity compared to copper. Advanced ceramics provide essential heat insulation for missile cones and space shuttles, ensuring durability under extreme conditions.

Additionally, ceramics can contribute to environmental sustainability. They can absorb toxic waste, purify water, and reduce pollution when appropriately applied. These qualities make ceramics a versatile and beneficial choice across various industrial and environmental applications.

Things to Consider Regarding Ceramics

If ceramic manufacturing aligns with your needs, the next crucial step is selecting a trustworthy manufacturer. With many companies prioritizing profit over quality, choosing the right one can be challenging and essential to avoid potential headaches. To assist you, we have curated a list of reputable manufacturers featured throughout this page. Take the time to review their profiles carefully.

While each company on our list maintains high standards of quality and customer service, selecting the best fit requires consideration of their products, services, and pricing that align with your requirements. After reviewing, we recommend selecting three or four manufacturers to contact directly. Share your specifications, inquire about their capabilities, and address any concerns you may have. Compare their responses to make an informed decision. Best of luck in your selection process!

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services