They first aided humans in the smelting of copper, tin and iron. A ceramic crucible is simply a crucible made from a ceramic material, like kiln-fired clay. Read More…

As a manufacturer and stocking distributor of industrial and technical ceramics, LSP carries the most diversified inventory of ceramic tubes, spacers, bushings, etc. in the industry.

C-Mac International manufactures custom advanced technical ceramic solutions. Our specialties are Zirconia (MgO stabilized and Yttria stabilized), Alumina (90%, 96%, and 99.5% purity), and Tungsten Carbide (Cobalt and Nickel Binder). We also work with steatite, cordierite, silicon nitride, ceramic crucibles, and crushable ceramics. We prioritize customer needs - we have a 48-hour delivery on...

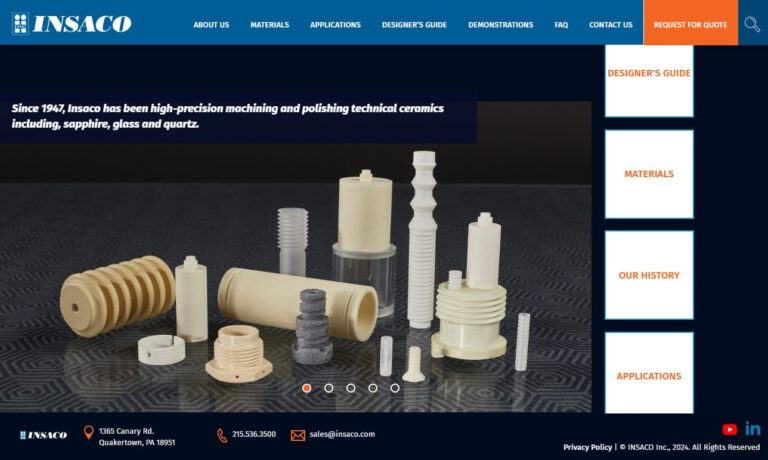

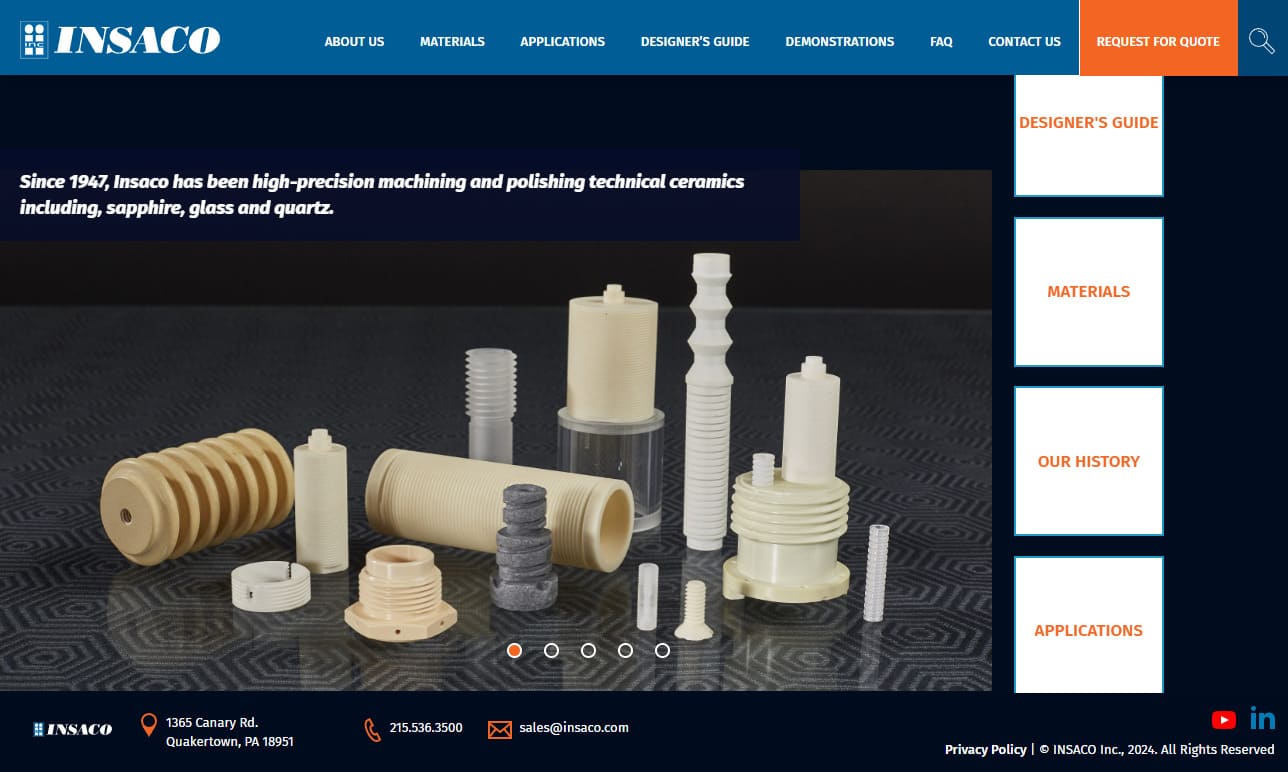

Insaco provides custom grinding and machining services to fabricate precision parts from sapphire, quartz, and most technical ceramics including alumina, zirconia, silicon carbide, silicon nitride, aluminum nitride, and others.

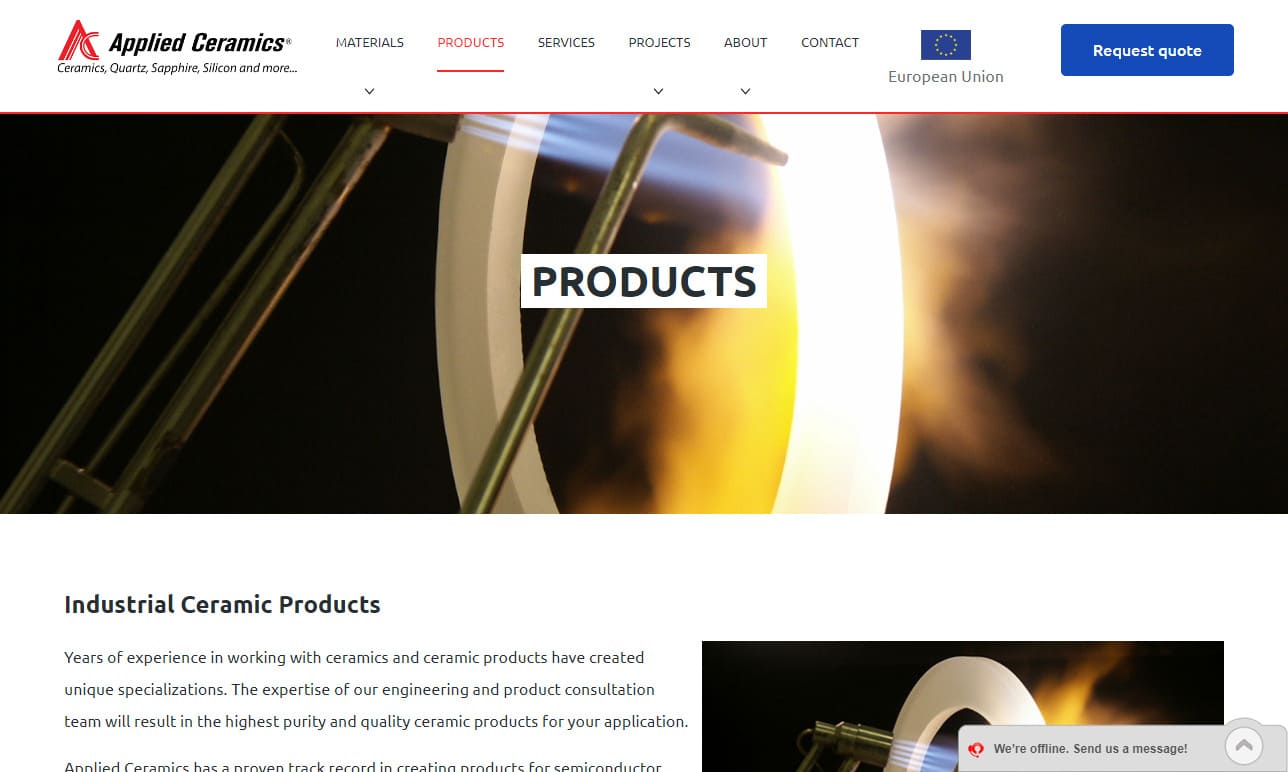

Applied Ceramics is a fabricator of custom-made ceramic parts designed for semiconductor, solar, fuel cell, oil drilling, nuclear, and numerous other industries. Materials include ACI-995 Alumina, Zirconia, and more. Our extensive experience with precision designs supported by our team of specialists ensures that our customers have the ideal solution to meet the needs of their application. To get ...

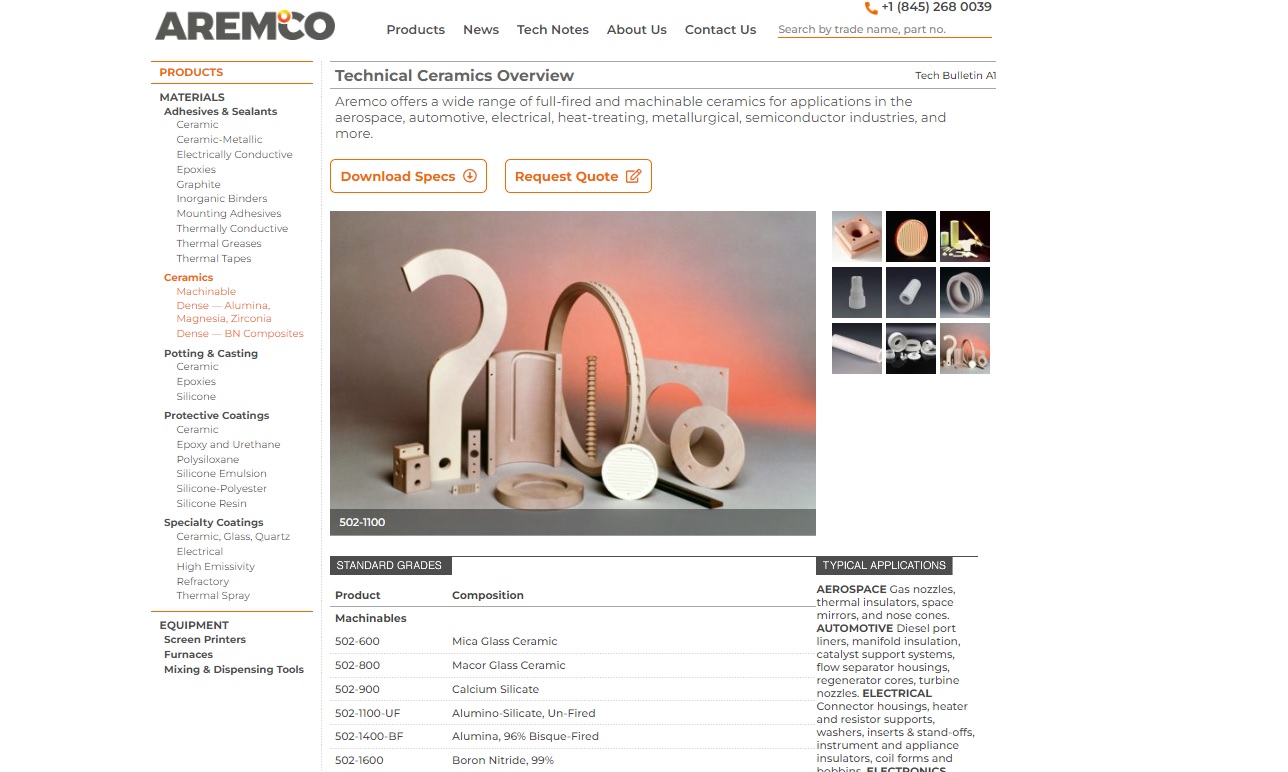

Aremco is a leader in the custom formulation of advanced industrial materials including technical ceramics. Offering many capabilities for a broad range of machinable & dense ceramic materials, Aremco serves aerospace, automotive, electrical, electronics, heat treating, metallurgical, petrochemical & plastics applications with superior finished ceramic parts. 100’s of standard industrial...

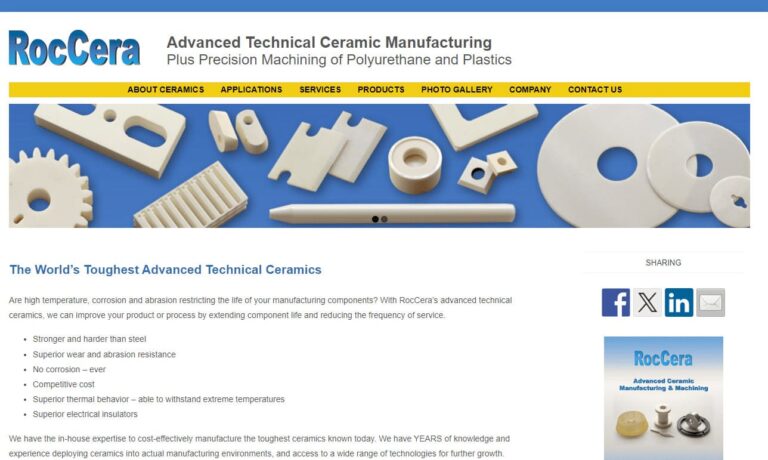

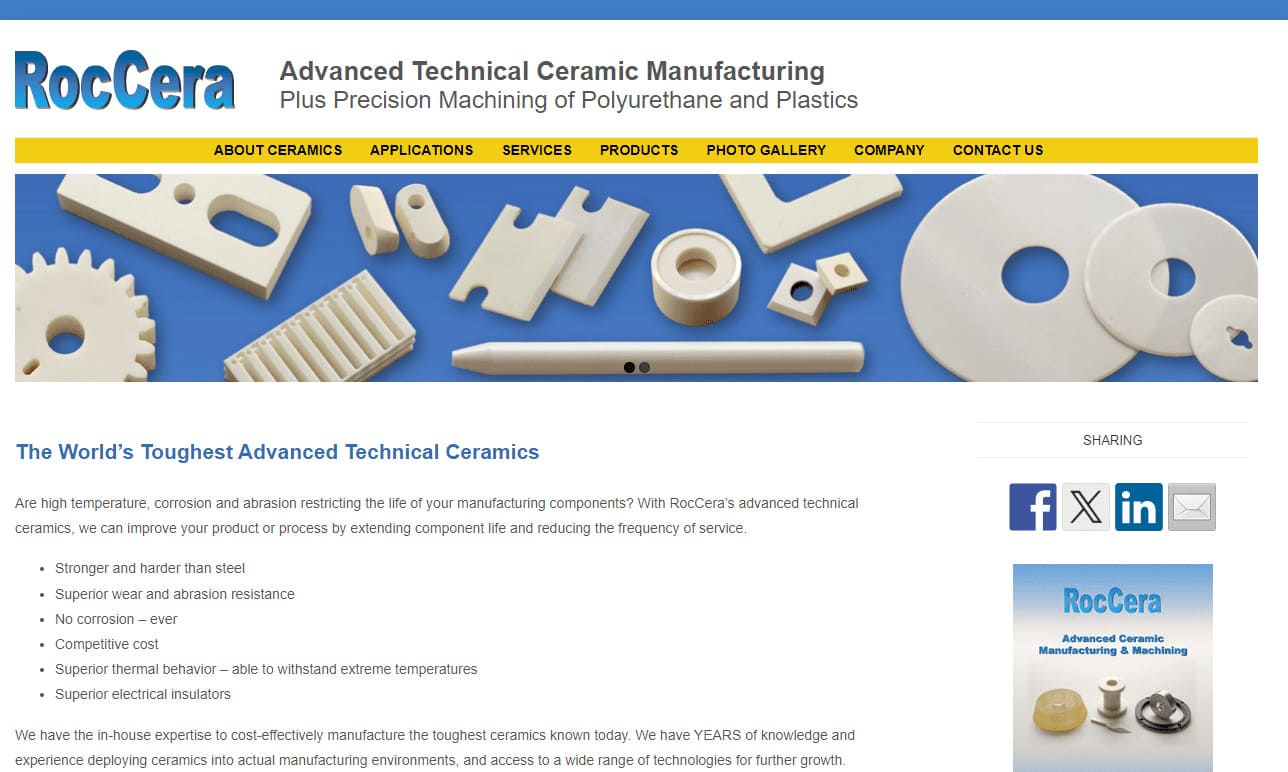

RocCera designs high-performance ceramic components. With a relentless pursuit of excellence and innovation, we have positioned ourselves as a leading provider of custom ceramic solutions catering to a diverse range of industries. Specializing in advanced technical ceramics, RocCera boasts a versatile portfolio that includes the manufacturing of ceramic components for various applications. Our...

As an ISO 9000 and QS 9000 company, CeramTec North America offers ceramic products such as ceramic insulators, ceramic cutting tools, ceramic substrates and ceramic-to-metal joints. We are one of the world's largest ceramic manufacturers that offer custom-engineered high-tech ceramics.

More Ceramic Crucible Manufacturers

Chemically and physically stable at high temperatures, or refractory, ceramic crucibles are used for working with materials that can only be manipulated at very high temperatures, such as metals, pigments and glasses.

Ceramics are nonmetallic, crystalline, inorganic or amorphous solids that have themselves been fired, cooled and glazed. Their surfaces are smooth and relatively inert. This inertness is crucial to the crucible, as a reactive surface would likely, at a high enough temperature, cause the materials within the crucible to mix with the crucible's own materials.

Though it is established that a ceramic almost certainly must be made of ceramic material, a customer must still make a decision about what kind of ceramic material he or she will select.

Ceramic crucibles can be made from a variety of base materials, such as silica, zircon, spinel, alumina and magnesite, and the desired chemical composition truly depends upon the crucible's intended application. Each chemical composition reacts differently to heat and pressure.

Alumina crucibles, for example, enjoy a rather widespread usage because they withstand a wide variety of temperature environments and because they are relatively inexpensive. Ceramic crucibles are commonly used in manufacturing, particularly in the areas of metallurgy, analysis and quality control. They also serve as common tools in such research fields as earth science, material science and engineering.

Additionally, ceramic crucibles are common, of course, in the arts, particularly with metalwork, pigment work and clay. Other characteristics that a customer should consider include total capacity, overall shape, wall thickness and bottom thickness.

Though in their early days they were frequently irregularly shaped, inconsistently thick and not terribly refractory, modern ceramic crucibles have evolved to have the ability to be used at incredibly high temperatures and pressures, and can be manufactured to nearly limitless custom specifications.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services