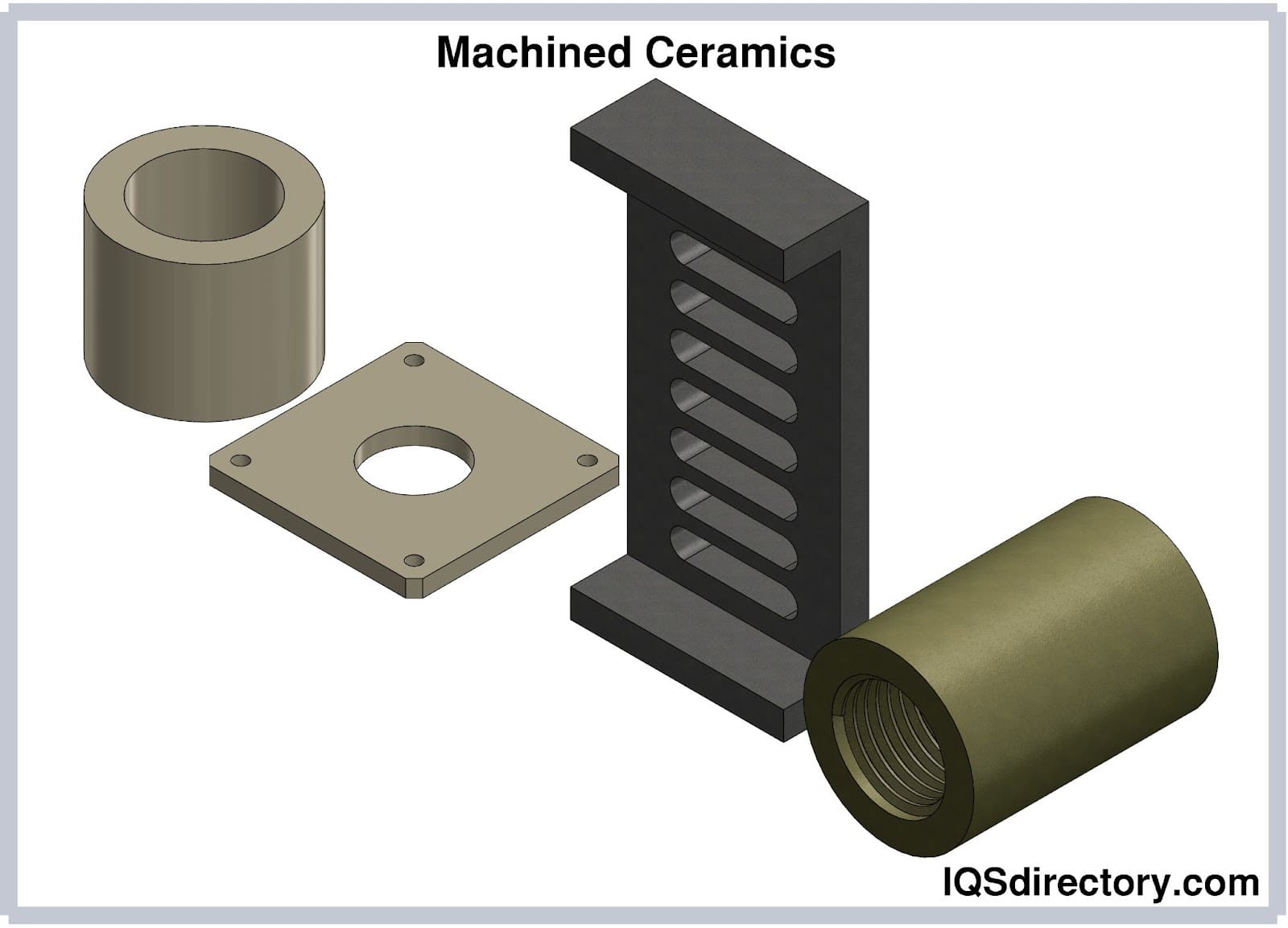

Ceramic machining is the process of designing and creating precision ceramic components. Numerous machining processes are used to produce an effective ceramic product. Read More…

As a manufacturer and stocking distributor of industrial and technical ceramics, LSP carries the most diversified inventory of ceramic tubes, spacers, bushings, etc. in the industry.

C-Mac International manufactures custom advanced technical ceramic solutions. Our specialties are Zirconia (MgO stabilized and Yttria stabilized), Alumina (90%, 96%, and 99.5% purity), and Tungsten Carbide (Cobalt and Nickel Binder). We also work with steatite, cordierite, silicon nitride, ceramic crucibles, and crushable ceramics. We prioritize customer needs - we have a 48-hour delivery on...

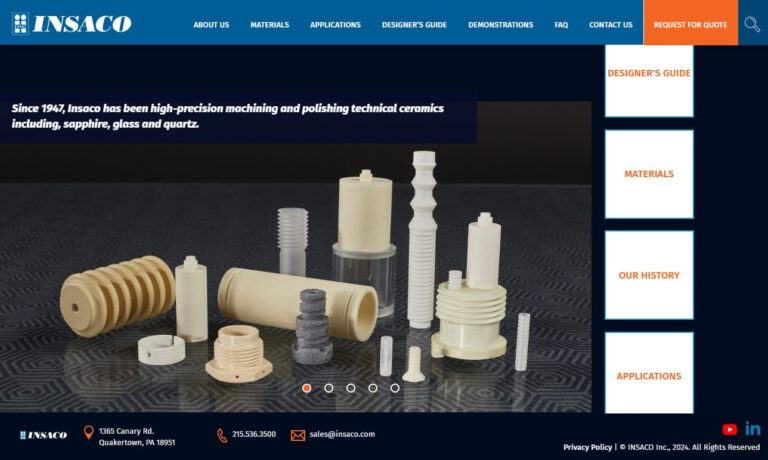

Insaco provides custom grinding and machining services to fabricate precision parts from sapphire, quartz, and most technical ceramics including alumina, zirconia, silicon carbide, silicon nitride, aluminum nitride, and others.

Applied Ceramics is a fabricator of custom-made ceramic parts designed for semiconductor, solar, fuel cell, oil drilling, nuclear, and numerous other industries. Materials include ACI-995 Alumina, Zirconia, and more. Our extensive experience with precision designs supported by our team of specialists ensures that our customers have the ideal solution to meet the needs of their application. To get ...

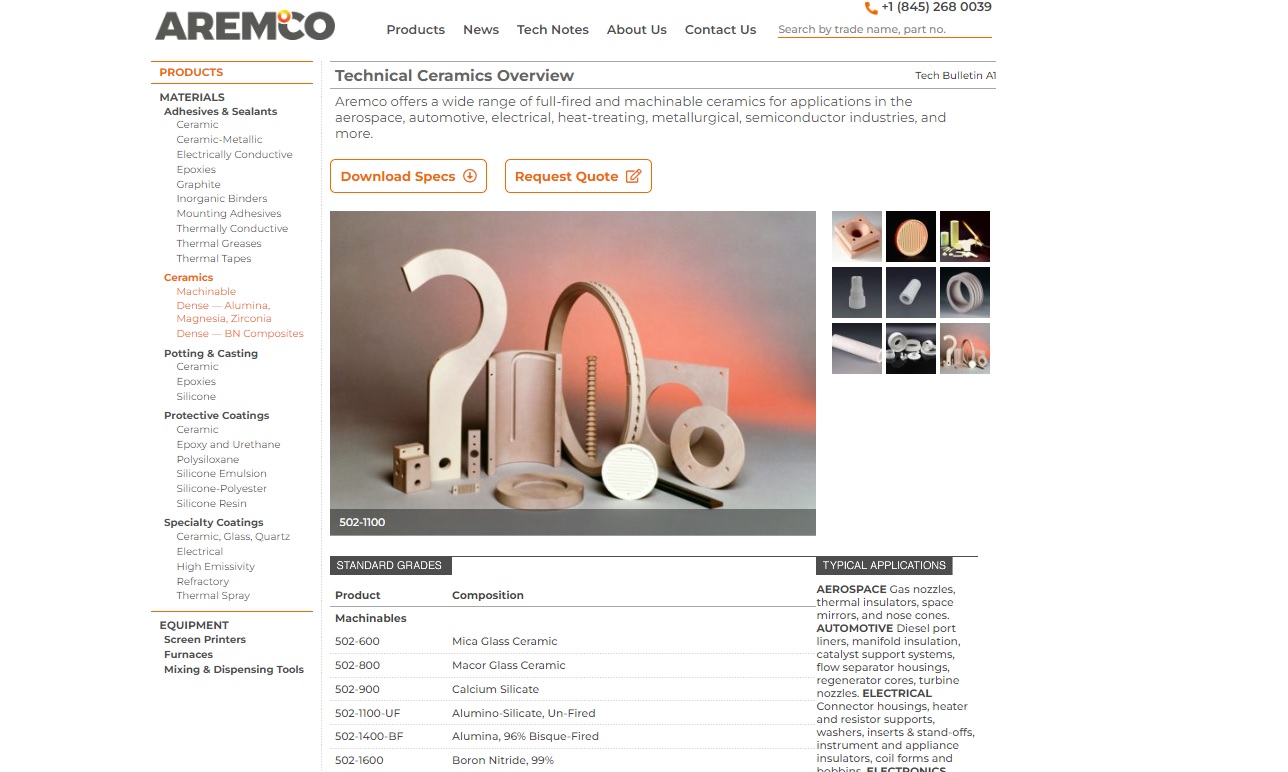

Aremco is a leader in the custom formulation of advanced industrial materials including technical ceramics. Offering many capabilities for a broad range of machinable & dense ceramic materials, Aremco serves aerospace, automotive, electrical, electronics, heat treating, metallurgical, petrochemical & plastics applications with superior finished ceramic parts. 100’s of standard industrial...

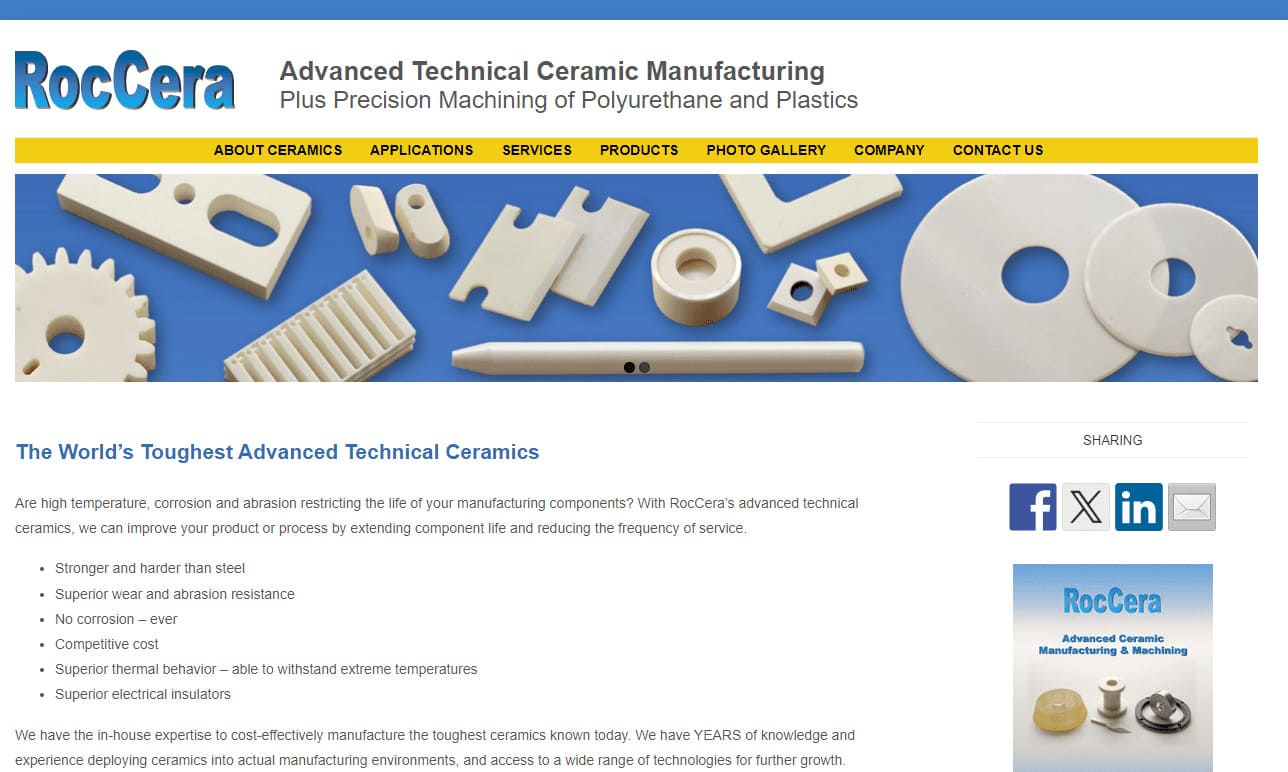

RocCera designs high-performance ceramic components. With a relentless pursuit of excellence and innovation, we have positioned ourselves as a leading provider of custom ceramic solutions catering to a diverse range of industries. Specializing in advanced technical ceramics, RocCera boasts a versatile portfolio that includes the manufacturing of ceramic components for various applications. Our...

As an ISO 9000 and QS 9000 company, CeramTec North America offers ceramic products such as ceramic insulators, ceramic cutting tools, ceramic substrates and ceramic-to-metal joints. We are one of the world's largest ceramic manufacturers that offer custom-engineered high-tech ceramics.

More Ceramic Machining Manufacturers

What is Ceramic Machining?

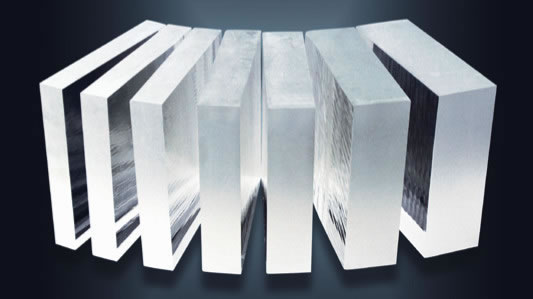

Ceramic machining is the process of designing and creating precision ceramic components. Numerous machining processes are used to produce an effective ceramic product. Forming, burning, and finishing are all steps involved in the ceramic machining process.

Ceramic Machining Processes

The different types of ceramic machining include:

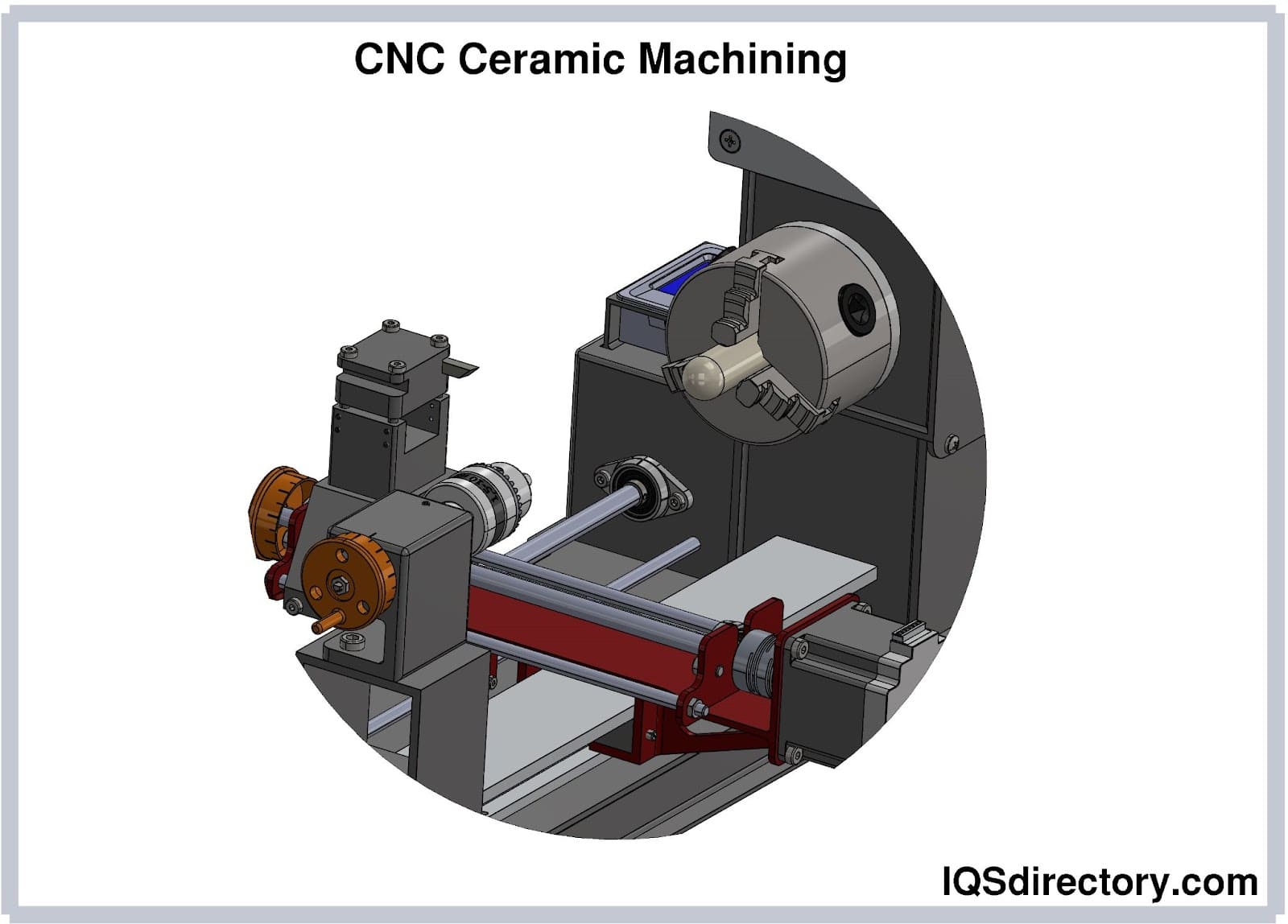

CNC Milling

Computer numerical control milling is referred to as CNC milling. Drilling and cutting are closely related to milling, and CNC milling machines can execute both tasks at various angles. CNC milling is a highly configurable automated machining process.

The machinery utilized for this approach relies on computerized controls and specialized cutting tools to gradually remove material from the workpiece to produce the desired output. The four steps of manufacturing for milling are the same as for other machining types. These are the stages:

- The creation of the product's CAD (computer-aided design) model

- CNC program creation from the CAD model

- The CNC milling machine's operational setup

- The milling operation's execution

Depending on the cutting operations performed and the characteristics of the cut material, CNC milling machines can be either horizontally or vertically oriented.

Rotating multipoint (or "multi-tooth") cutting tools on the milling machine carry out the required milling operations as directed by the CNC program. Climb milling methods are milling operations in which the machine feeds in the target material while the cutting tool rotates.

Contrarily, traditional milling methods are milling operations that feed the movable workpiece against the rotation of the tool. The product moves on to finishing and post-processing activities when the milling operations are finished.

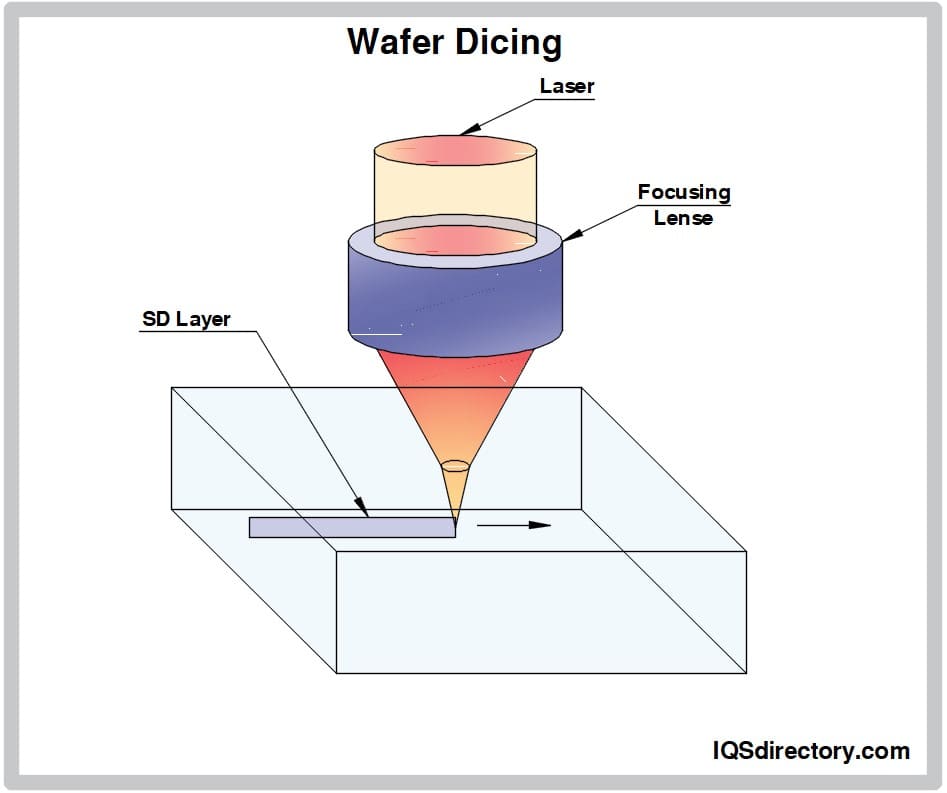

Wafer Dicing

Dice are extracted from a wafer of semiconducting material using a method called wafer dicing. Scribing and breaking, mechanical sawing, or laser-cutting procedures are used to achieve this separation.

The leftover individual silicon chips from the dicing process are enclosed in chip carriers and then employed in a number of electronic applications. Wafers can typically be tape mounted on a film frame for easier handling.

The wafers can also be wax mounted to the glass to improve cutting precision. The various wafer dicing operations include:

- Cutting a bevel: The target substrate is given a V-shaped groove or chamfer as a result of this cutting operation.

- Burr mitigation: The burr produced on the cut edge of the target material can be reduced using a combination of machining tools and speeds.

- Chip control: To ensure edge chipping levels stay within specifications, operators closely monitor variables like feed, speed, and coolant flow.

- Scribing: Marking the wafer with a scribe can help break operations later.

- Wraparound metallization: In microwave circuits, wraparound metallization has strong grounding characteristics.

- Cleaning and packing: After the dicing procedures are finished, a thorough die cleaning ensures that the finished product is spotless and ready for packaging.

Some procedures may apply a protective layer to the target substrate before dicing starts.

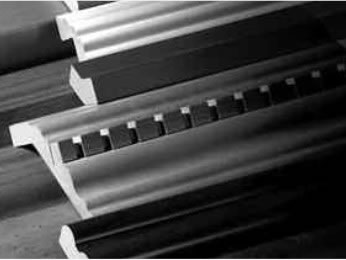

Surface Grinding

Surface grinding is a typical procedure for smoothing out and refining. A grinding wheel or disc smooths off the target material's surface in this operation and then refines the workpiece's surface and edges to extremely precise tolerances.

Surface grinders come in three different categories:

- Horizontal spindle grinders: These grinding procedures produce highly accurate results because the flat edge of the grinding wheel makes touch with the workpiece .

- Vertical spindle grinders: Vertical spindle or wheel-face grinders, as opposed to horizontal spindle grinders, remove a lot of material at once. The grinding wheel's face, not its edge, makes contact with the desired surface.

- Single- or double-disc grinders: Disc grinders can be oriented horizontally or vertically and frequently grind two sides of a workpiece simultaneously.

Core Drilling

During core drilling, a cylindrical core is taken out of the drill hole. There are three essential components to a core drill:

- drill bit or bits

- motor

- handle

Usually, the drill bit(s) are coated with diamond or carbide. Concrete core drills often employ drill bits with diamond coatings, whereas masonry core drills typically use bits with carbide coatings.

Today's core drills come in a wide variety. These range from tiny core drills used by homeowners for DIY projects to enormous core drills used to cut concrete in large-scale construction projects. Core drilling enables the safe removal and examination of a material's core. The core is disregarded in other instances where the goal is merely the creation of a hole.

Choosing the Correct Ceramic Machining Company

To make sure you have the most productive outcome when purchasing Ceramic Machining from a Ceramic Machining Company, it is important to compare at least 5 or 6 Companies using our Ceramic Machining directory. Each Ceramic Machining Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Ceramic Machining business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Ceramic Machining businesses with the same message.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services