Ceramic electrical insulators are inserted into control boards and boxes as a heat sink but are most frequently employed to create non-conductive bridges between electronic components. They are formed of porous clay that is either red, brown, or white, and they have high dielectric strength and steady and minimal electrical loss. In addition, they are simple to maintain and immune to stains and other residue types. Because of their incredibly high electrical current resistance, ceramics have been utilized as electric insulators for a long time. Read More…

As a manufacturer and stocking distributor of industrial and technical ceramics, LSP carries the most diversified inventory of ceramic tubes, spacers, bushings, etc. in the industry.

C-Mac International manufactures custom advanced technical ceramic solutions. Our specialties are Zirconia (MgO stabilized and Yttria stabilized), Alumina (90%, 96%, and 99.5% purity), and Tungsten Carbide (Cobalt and Nickel Binder). We also work with steatite, cordierite, silicon nitride, ceramic crucibles, and crushable ceramics. We prioritize customer needs - we have a 48-hour delivery on...

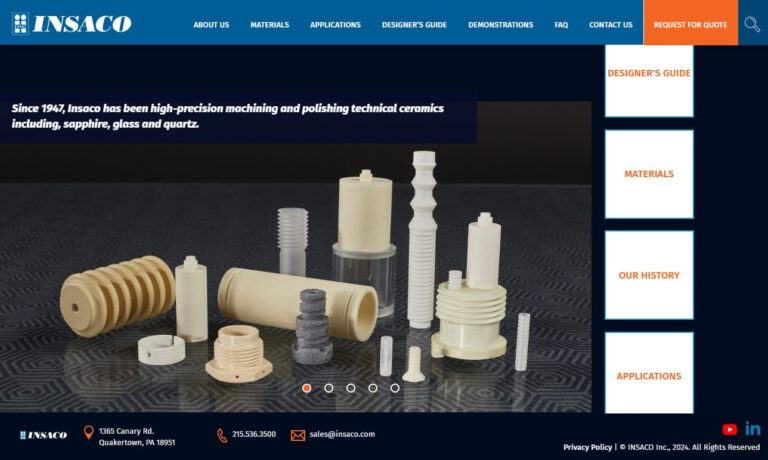

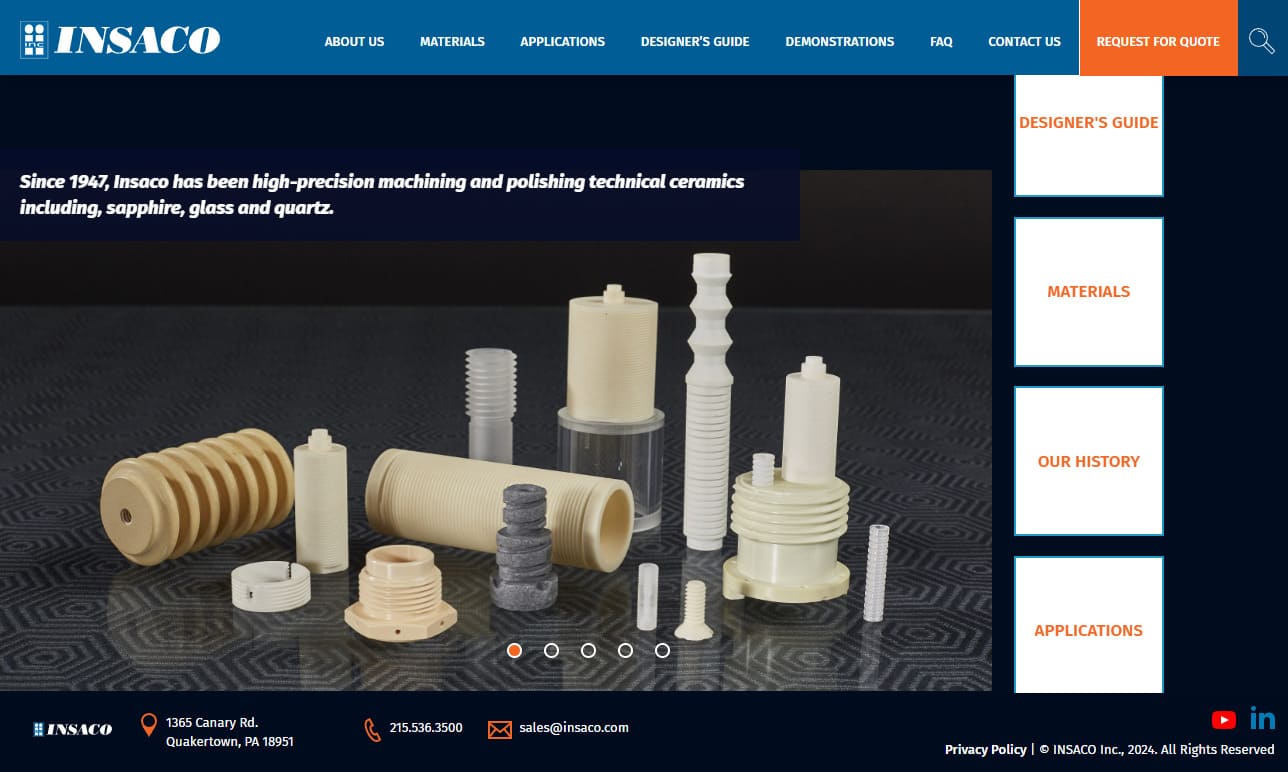

Insaco provides custom grinding and machining services to fabricate precision parts from sapphire, quartz, and most technical ceramics including alumina, zirconia, silicon carbide, silicon nitride, aluminum nitride, and others.

Applied Ceramics is a fabricator of custom-made ceramic parts designed for semiconductor, solar, fuel cell, oil drilling, nuclear, and numerous other industries. Materials include ACI-995 Alumina, Zirconia, and more. Our extensive experience with precision designs supported by our team of specialists ensures that our customers have the ideal solution to meet the needs of their application. To get ...

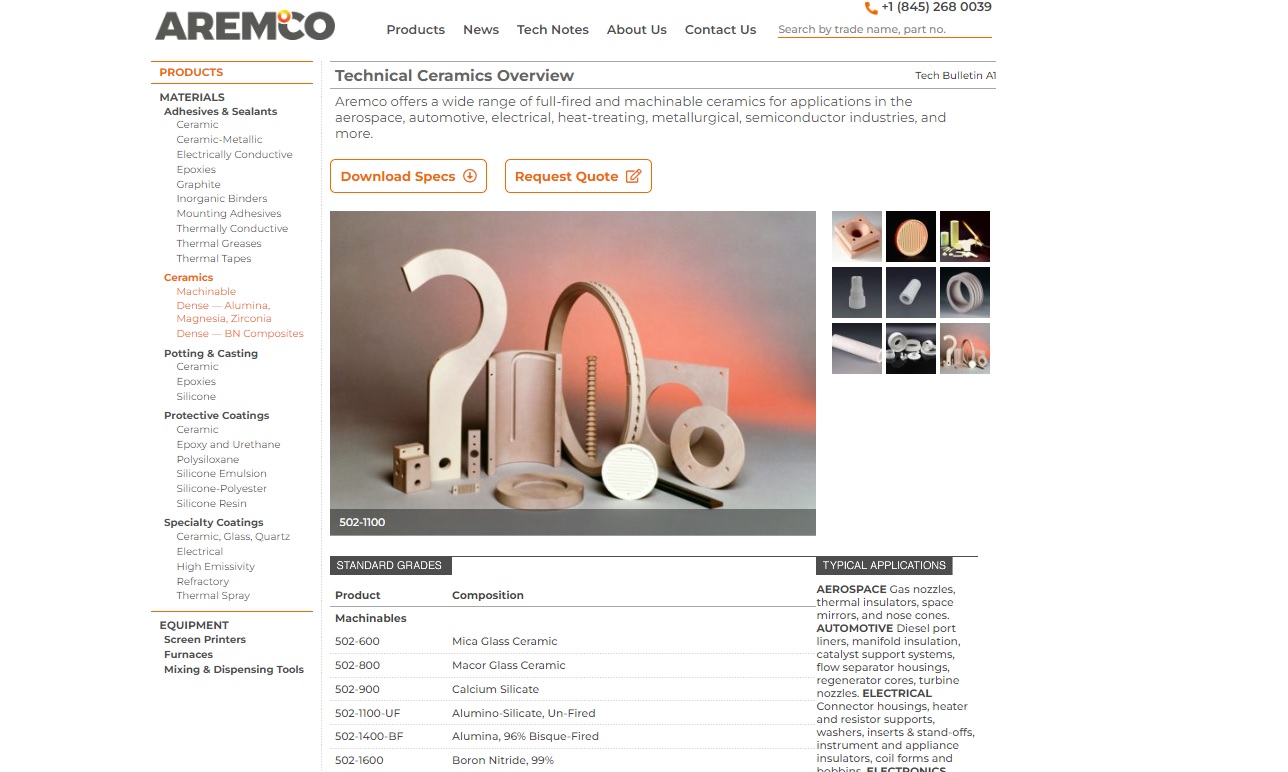

Aremco is a leader in the custom formulation of advanced industrial materials including technical ceramics. Offering many capabilities for a broad range of machinable & dense ceramic materials, Aremco serves aerospace, automotive, electrical, electronics, heat treating, metallurgical, petrochemical & plastics applications with superior finished ceramic parts. 100’s of standard industrial...

RocCera designs high-performance ceramic components. With a relentless pursuit of excellence and innovation, we have positioned ourselves as a leading provider of custom ceramic solutions catering to a diverse range of industries. Specializing in advanced technical ceramics, RocCera boasts a versatile portfolio that includes the manufacturing of ceramic components for various applications. Our...

As an ISO 9000 and QS 9000 company, CeramTec North America offers ceramic products such as ceramic insulators, ceramic cutting tools, ceramic substrates and ceramic-to-metal joints. We are one of the world's largest ceramic manufacturers that offer custom-engineered high-tech ceramics.

More Ceramic Insulator Manufacturers

How Ceramic Insulators are Used

From power distribution centers to mobile phones, ceramic insulators are used in various electronic applications. Due to their non-conductivity and remarkable mechanical robustness, ceramics make excellent insulating materials. Power lines, coaxial cables, and circuit boards are examples of places where ceramic insulators shield against electromagnetic (EM) waves, fire risks, power surges, and short circuits. Ceramic insulators are widely used because of their capacity to retain heat. They are also simple to build and form into various designs. As a result, they play a major role in many applications used for controlling power.

Uses of Ceramic Insulators

Poles

An element of a pole ceramic insulator is a spool insulator fastened to a bracket, which is connected to the top and bottom of the spool by a thin rod that runs through the middle of the insulator. A bolt in the middle of the bracket is used to fasten them to surfaces such as walls, poles, or ceilings. Ceramic pole insulators can adapt and change when the connected line's angle does.

Safety

The main job of insulators is to control current flow and prevent it from going toward the earth. Safety ceramic insulators stay put and offer insulation if wires are severed and fall to the ground. Wires won't touch the earth because their placement is ensured. Different connections are produced for ceramic safety insulators based on the application’s demands. For example, if a pole were to fall, the ceramic insulator would ensure that there would be no electricity in the lowest part of the system.

Heat Applications

Ceramic insulators are commonly employed in applications where there is tremendous heat. In furnaces, heaters, and ovens, ceramic insulators support the heating elements. Ceramic is the ideal insulation material for heated applications because of its durability, extended life, and capacity to maintain its shape and size under pressure. Ceramic insulators support and divide heating elements in many heaters.

Mechanical Stress

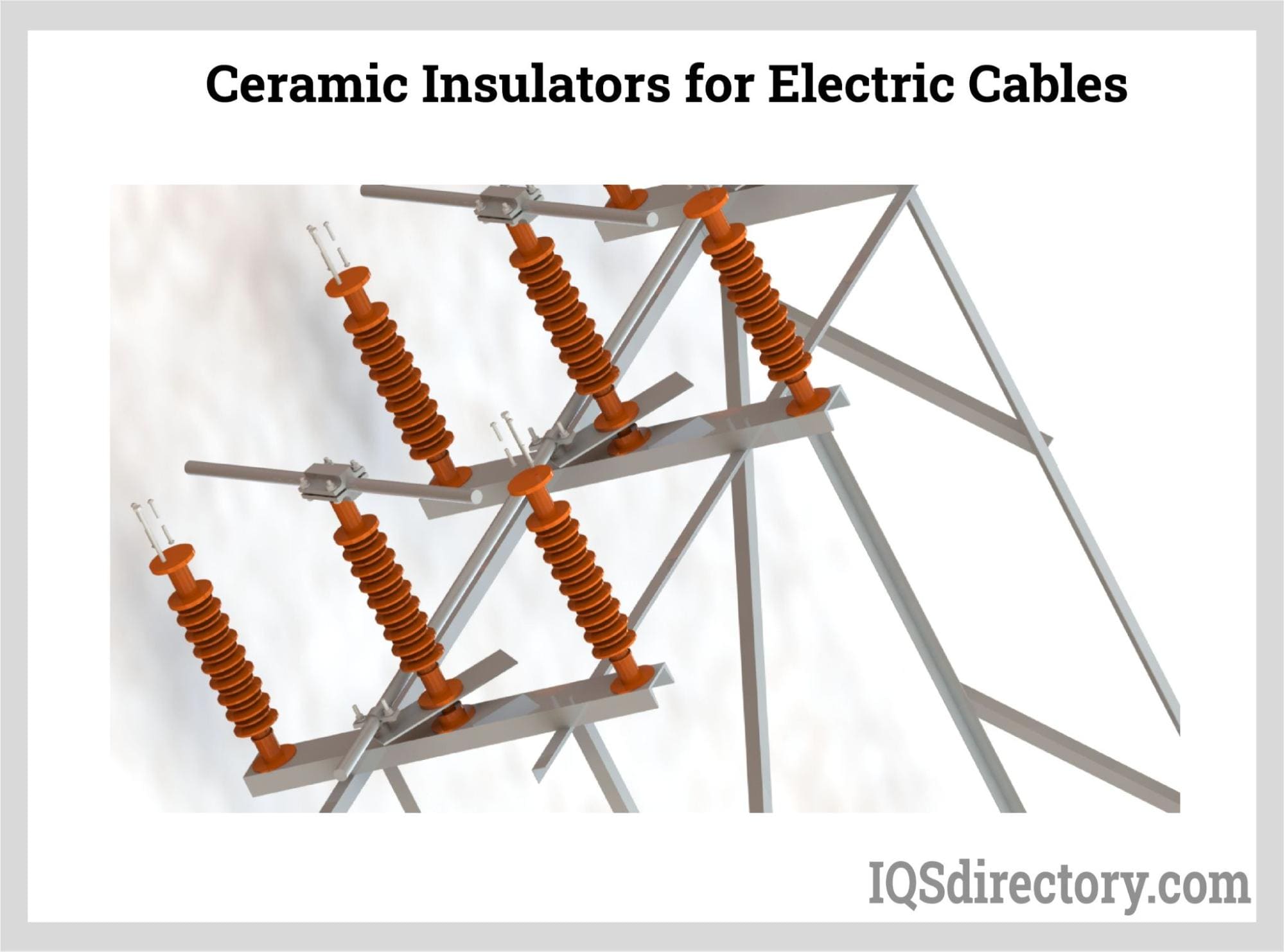

Ceramic insulators with mechanical tension are intended to be used when cables or wires hanging overhead pull on the insulator. They are used with overhead wires, radio antennas, and power lines, like support ceramic insulators. They might be positioned in the space between two power lines to keep them apart. Ceramic insulators with mechanical tension are ideal for keeping wires taut and straight.

Types of Ceramic Insulators

Ceramic Standoff Insulators

Ceramic standoff insulators limit current to the intended path and prevent electricity from hopping between components. They can be found in a variety of settings, but transformer current regulators are where they are mostly found. Ceramic standoff insulators guard against power deterioration and cut down on energy waste.

Standoff ceramic insulators can survive high temperatures produced by low-speed resistors, just like most ceramic insulators can. They come in cylindrical shapes that are round, square, or rectangular and are great insulators for installing fuses or heavy-duty cables.

Ceramic Suspension Insulators

To carry electricity lines, suspension ceramic insulators are suspended from the cross arms of towers or other supporting structures. The disks hung on top of one another, known as a string, are the primary components of the remaining ceramic insulators. Metal connections connect ceramic suspension insulator threads.

Hollow Ceramic Insulators

Bushings for power and instrument transformers, wall bushings, circuit breakers, surge arresters, and cable terminals are all made of hollow ceramic insulators. They are manufactured in various sizes with cylindrical, conical, or spherical body shapes. High mechanical resistance and electrical insulation are both possible with hollow ceramic insulators.

Ceramic Insulator Benefits

Strength of Dielectric

For various electrical wiring and circuits, ceramic insulators are used because of this particular characteristic. Despite the circumstances, however, ceramic insulators deliver a great performance due to their high dielectric strength and minimal electrical loss.

Corrosion Resistance

Ceramic insulators are immune to the effects of rust and corrosion since they contain no metal at all. They can, therefore, be mounted on fence posts, power line crossbars, and other exterior electrical lines without being influenced by the surrounding environment.

Hardness

Since ceramic materials are made of powder, it might seem that they wouldn't be durable enough to sustain repeated use. However, ceramic insulators are four times tougher than stainless steel, which is astounding. This specific attribute guarantees their longevity.

Resistance to Wear

The capacity of ceramic insulators to maintain their quality and look goes hand in hand with their hardness. Hardness and wear resistance work together to ensure robustness and durability, which are crucial for sustainability.

Technical Features

No matter the circumstances, any component needed to defend electrical wiring must maintain its mechanical integrity. Ceramic insulators are very good at preserving their mechanical characteristics to offer reliable performance over time.

Choosing the Proper Ceramic Insulators Supplier

To make sure you have the most productive outcome when purchasing Ceramic Insulators from a Ceramic Insulators Supplier, it is important to compare at least 6 Manufacturers using our list of Ceramic Insulators suppliers. Each Ceramic Insulators Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Ceramic Insulators company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Ceramic Insulators companies with the same form.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services