Ceramic spacers are useful in a variety of applications due to their versatility in both form and chemical composition. For instance, ceramic tile spacers are ½ inch solid squares that are beneficial for tiling applications in which they are used to space the tiles evenly prior to grouting. Read More…

As a manufacturer and stocking distributor of industrial and technical ceramics, LSP carries the most diversified inventory of ceramic tubes, spacers, bushings, etc. in the industry.

C-Mac International manufactures custom advanced technical ceramic solutions. Our specialties are Zirconia (MgO stabilized and Yttria stabilized), Alumina (90%, 96%, and 99.5% purity), and Tungsten Carbide (Cobalt and Nickel Binder). We also work with steatite, cordierite, silicon nitride, ceramic crucibles, and crushable ceramics. We prioritize customer needs - we have a 48-hour delivery on...

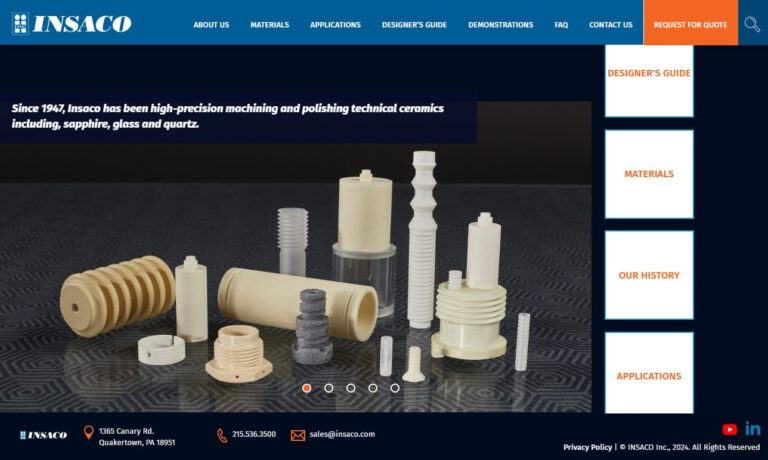

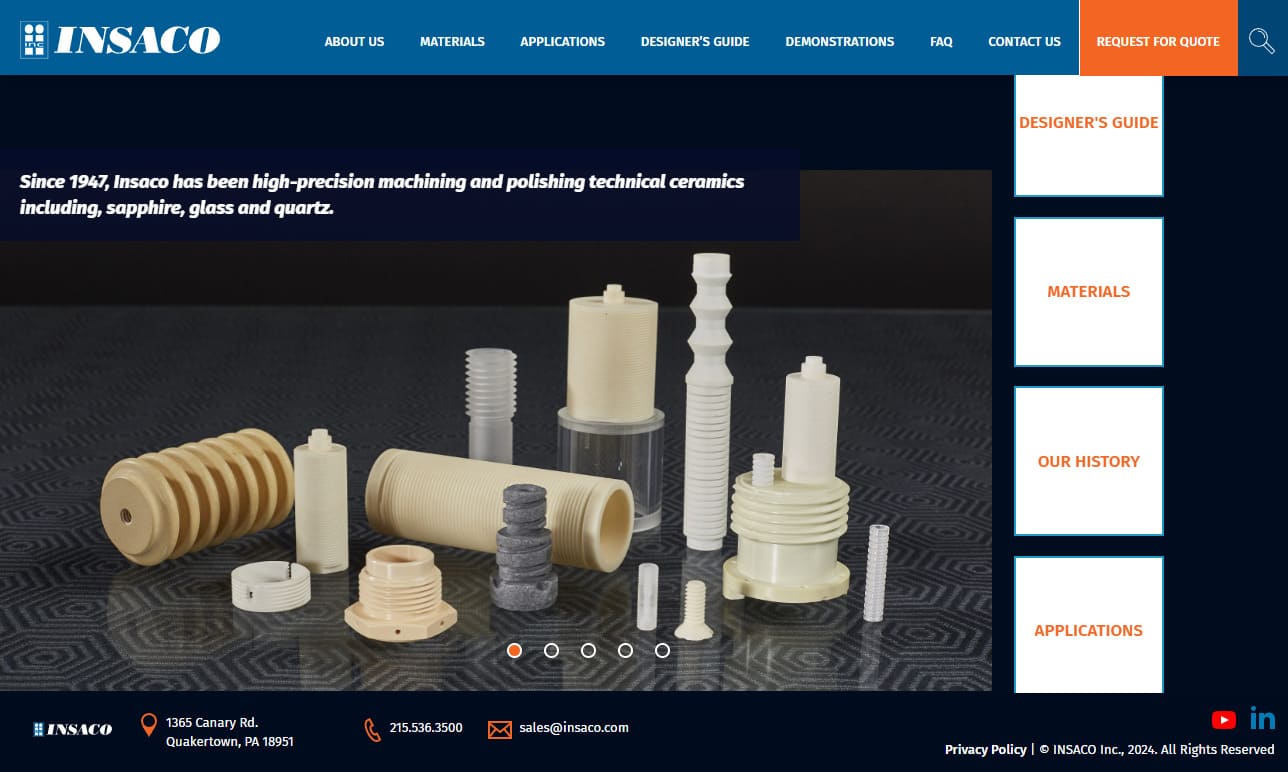

Insaco provides custom grinding and machining services to fabricate precision parts from sapphire, quartz, and most technical ceramics including alumina, zirconia, silicon carbide, silicon nitride, aluminum nitride, and others.

Applied Ceramics is a fabricator of custom-made ceramic parts designed for semiconductor, solar, fuel cell, oil drilling, nuclear, and numerous other industries. Materials include ACI-995 Alumina, Zirconia, and more. Our extensive experience with precision designs supported by our team of specialists ensures that our customers have the ideal solution to meet the needs of their application. To get ...

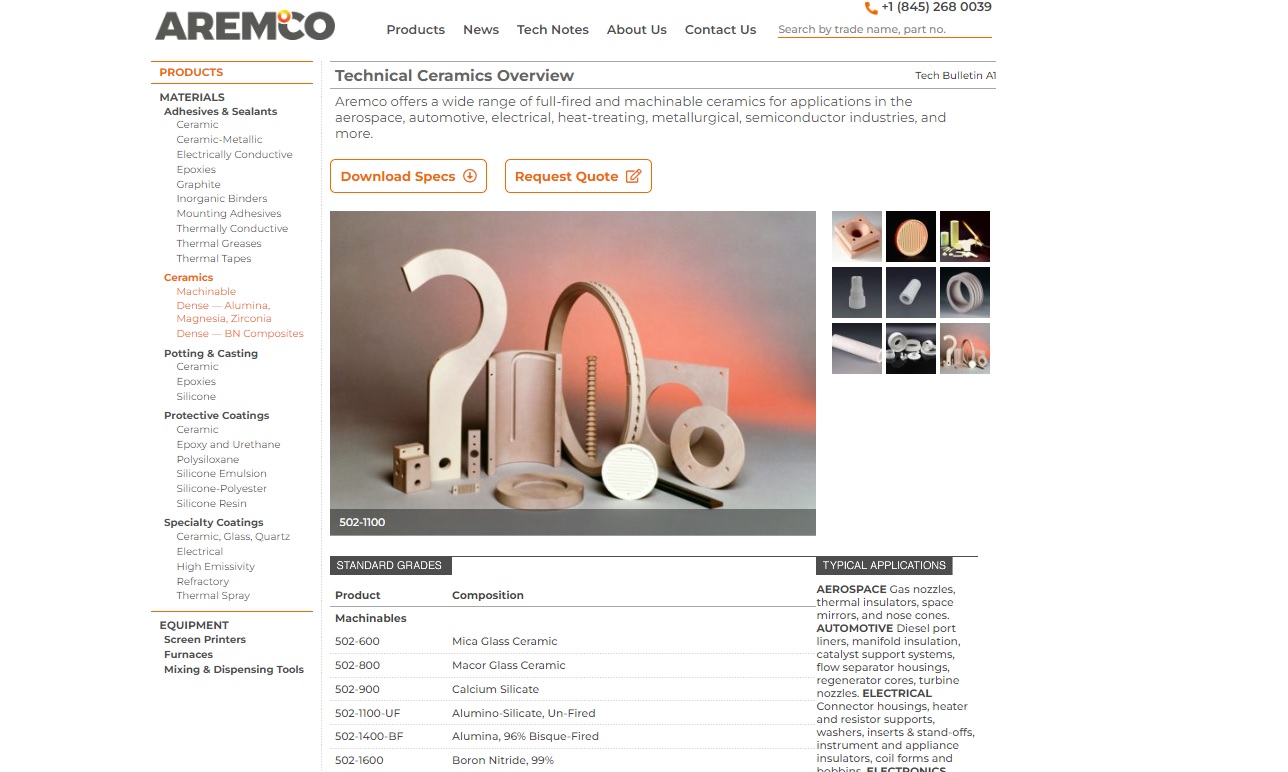

Aremco is a leader in the custom formulation of advanced industrial materials including technical ceramics. Offering many capabilities for a broad range of machinable & dense ceramic materials, Aremco serves aerospace, automotive, electrical, electronics, heat treating, metallurgical, petrochemical & plastics applications with superior finished ceramic parts. 100’s of standard industrial...

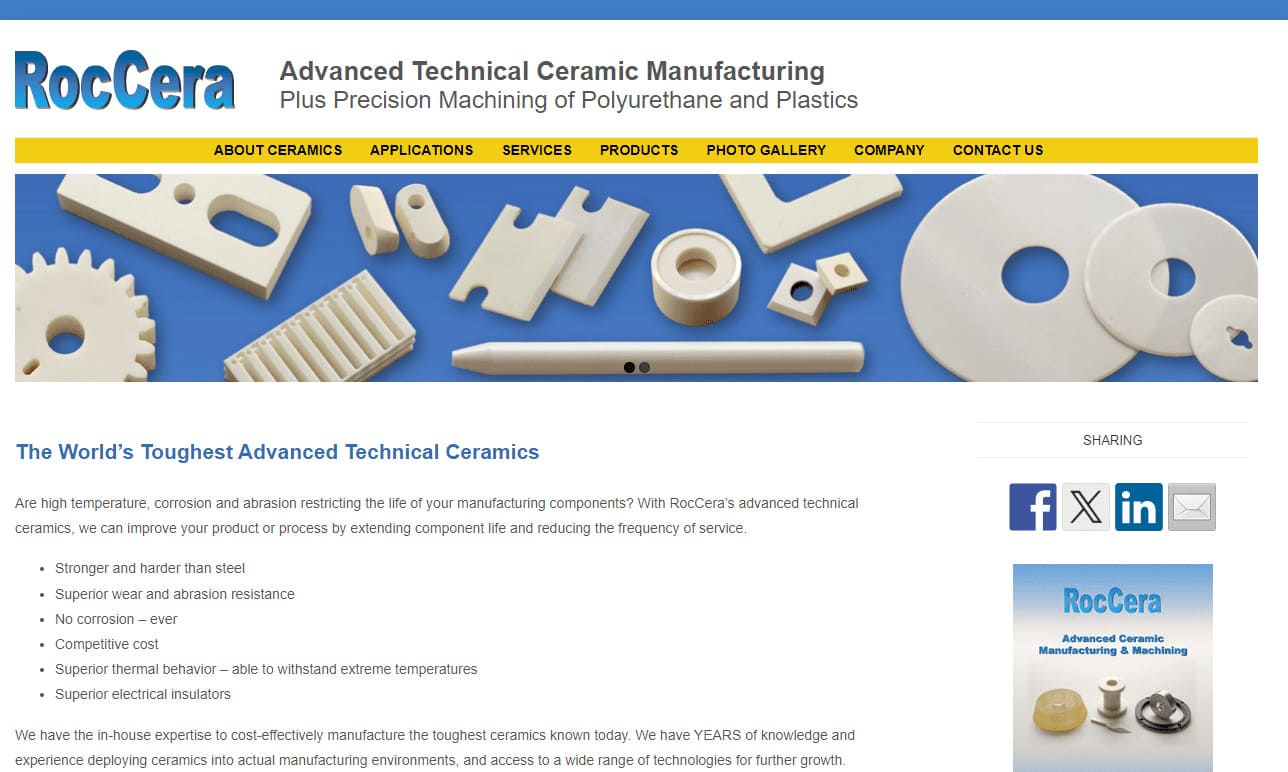

RocCera designs high-performance ceramic components. With a relentless pursuit of excellence and innovation, we have positioned ourselves as a leading provider of custom ceramic solutions catering to a diverse range of industries. Specializing in advanced technical ceramics, RocCera boasts a versatile portfolio that includes the manufacturing of ceramic components for various applications. Our...

As an ISO 9000 and QS 9000 company, CeramTec North America offers ceramic products such as ceramic insulators, ceramic cutting tools, ceramic substrates and ceramic-to-metal joints. We are one of the world's largest ceramic manufacturers that offer custom-engineered high-tech ceramics.

More Ceramic Spacer Manufacturers

In medical applications, ceramic spacers are used as replacement spinal discs and dental implants from hydroxyapatite ceramics, a ceramic that offers the natural mineral component of bone. Ceramic spacers are also used to support insulating bodies, particularly in electrical insulation such as power lines that use circular ceramic spacers between the poles.

Industries that utilize ceramic spacers include medical, heating and cooling, defense, construction, microelectronics, oil and petroleum, automotive and aerospace. Able to withstand high temperatures, chemicals and harsh weather conditions, ceramic spacers are highly durable as well as being cost-effective.

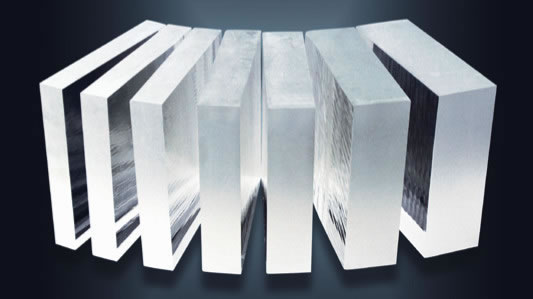

All ceramics share characteristics of having a crystalline structure; however ceramic spacers are typically categorized as technical ceramics, also known as engineering ceramics, or advanced ceramics. Ceramic spacers are most commonly formed from aluminum oxide, beryllium-oxide and aluminum nitride.

Aluminum oxides offer 20 times the thermal conductivity than most other oxides. Beryllium oxides are generally superior to aluminum oxides, excepting that beryllium oxides have a high toxicity. Aluminum nitride is a less toxic alternative to beryllium oxide with a low thermal expansion. These three ceramic compounds comprise ceramic spacers' raw materials, which begin the manufacturing process as fine powders.

Other minerals and materials may be added to enhance certain properties, such as with hydroxyapatite ceramics. After this, the powder material is prepped by ceramic spacer manufacturers for forming by adding water or another liquid additive.

The slurry or liquid material is then slip cast, extruded or injection molded into the desired shapes known as greenware, which are then placed in an extremely high heat oven and sintered. Next, the greenware becomes rigid ceramic, which can then be glazed or further processed by polishing, cutting or machining for ceramic spacer applications.

Ceramic spacers come in a wide range of shapes including circular, square, pyramid, t-shaped and many more.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services