Philadelphia Carbide Co.

Philadelphia Carbide Co.Request A Quote

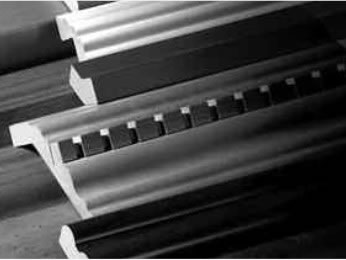

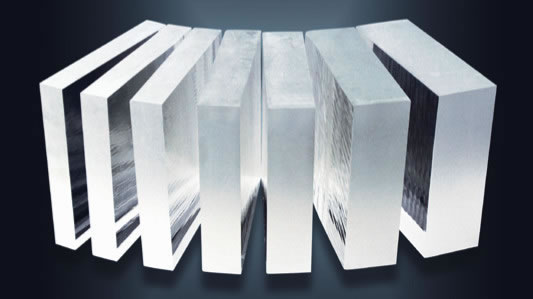

Oreland, PA | 215-885-0770Philadelphia Carbide Co., headquartered in Oreland, Pennsylvania, is a distinguished company that has been operating since 1957. With a specialization in manufacturing precision-ground wear parts, machine parts, and dies, Philadelphia Carbide Co. caters to the most demanding industrial applications. The company's expertise lies in working with a variety of materials, including tungsten carbide, silicon carbide, and ceramic materials. This description will focus on their capabilities and products related to ceramic materials. Philadelphia Carbide Co. offers a wide range of products made from ceramic materials, providing superior performance in challenging industrial environments. Their ceramic products include wear parts, machine parts, and dies specifically engineered to meet the demanding requirements of various industries. With a focus on ceramic materials, Philadelphia Carbide Co. provides components that exhibit excellent wear resistance, high temperature resistance, corrosion resistance, and electrical insulation properties. In addition to their extensive product line, Philadelphia Carbide Co. provides comprehensive services to support their customers in utilizing ceramic materials effectively. The company offers custom manufacturing and engineering services, working closely with clients to develop tailored solutions for their specific applications. Philadelphia Carbide Co.'s experienced technicians and engineers assist in material selection, design optimization, and the fabrication of ceramic components to meet precise specifications and requirements. Philadelphia Carbide Co. boasts advanced capabilities in working with ceramic materials. Their expertise includes precision grinding, machining, and finishing techniques to produce ceramic components with tight tolerances and exceptional surface quality. The company's state-of-the-art facilities and equipment enable them to work with a variety of ceramic materials, including alumina, zirconia, silicon carbide, and more. Philadelphia Carbide Co.'s skilled workforce ensures the highest level of quality and consistency in the manufacturing process. The ceramic materials and components provided by Philadelphia Carbide Co. find applications in a wide range of industries, including aerospace, automotive, electronics, energy, and manufacturing. The wear parts, machine parts, and dies manufactured from ceramic materials exhibit excellent durability, resistance to wear, and ability to withstand harsh operating conditions. Whether it's protecting critical components in high-temperature environments, providing electrical insulation, or enhancing performance and reliability, Philadelphia Carbide Co.'s ceramic products offer effective solutions for demanding industrial applications.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services