McDowell & Company

McDowell & CompanyRequest A Quote

Richardson, TX | 800-486-4748McDowell & Company, established in 1971 and headquartered in Richardson, Texas, is a leading ceramic manufacturing company specializing in the production of high-quality ceramics for various industries. With over five decades of expertise, McDowell & Company has gained a reputation for excellence in delivering innovative ceramic solutions to meet the diverse needs of its clients. McDowell & Company offers a wide range of ceramic products, carefully designed and manufactured to meet the exact specifications and requirements of its customers. The company's product portfolio includes ceramic components, such as substrates, insulators, bushings, wear parts, and precision components, which are used in industries like aerospace, automotive, electronics, telecommunications, and medical devices. Additionally, McDowell & Company manufactures ceramic tiles for architectural and interior design applications, known for their durability, aesthetic appeal, and versatility. These ceramic tiles are ideal for residential, commercial, and industrial projects. To support its customers throughout the entire ceramic manufacturing process, McDowell & Company provides a comprehensive range of services. T They offer expertise in material selection, product design, and manufacturing processes to ensure optimal performance and cost-effectiveness. McDowell & Company also assists clients in the prototyping phase, producing samples and conducting rigorous testing to validate the design and functionality of ceramic components. This iterative process helps refine the final product before full-scale production. With state-of-the-art facilities and advanced equipment, the company has the capabilities to handle large-scale ceramic manufacturing. They employ cutting-edge techniques, including precision machining, sintering, glazing, and finishing, to ensure consistent quality and meet tight tolerances. McDowell & Company's ceramic manufacturing capabilities set it apart as a leader in the industry. The company works with a wide range of ceramic materials, including alumina, zirconia, silicon carbide, silicon nitride, and various other advanced ceramic compositions, leveraging its materials expertise to select the most suitable ceramic material for each application. Advanced manufacturing techniques such as computer-aided design (CAD), computer-aided manufacturing (CAM), and computer numerical control (CNC) machining are employed to ensure precision and efficiency in the production process. Furthermore, the company maintains rigorous quality control measures at every stage of the manufacturing process, with a dedicated quality assurance team conducting stringent testing to ensure that each ceramic component or product meets or exceeds industry standards. With decades of experience serving various industries, McDowell & Company understands the unique requirements and challenges faced by its clients, providing tailored ceramic solutions that address specific industry needs.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

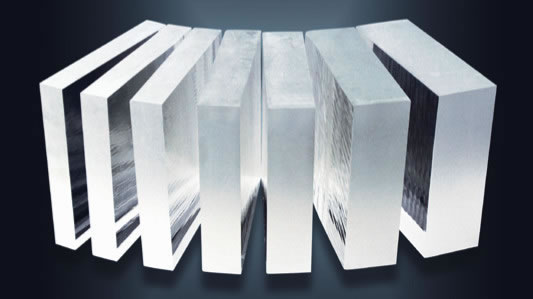

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

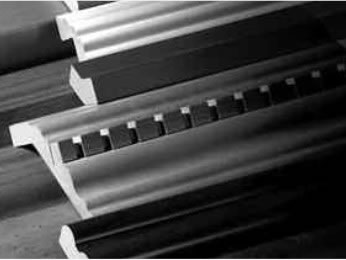

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services