GBSA Inc.

GBSA Inc.Request A Quote

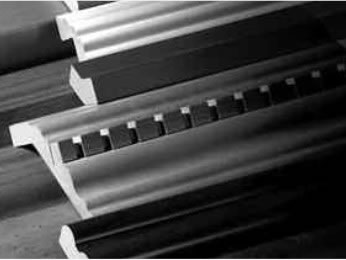

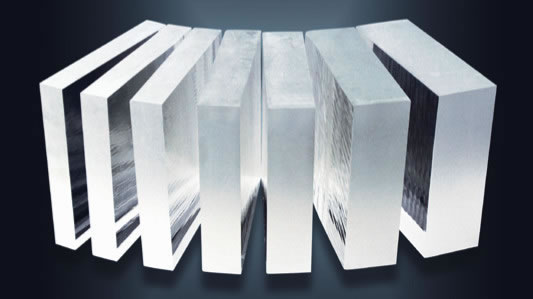

Chardon, OH | 800-837-4272GBSA Inc., founded in 1979 and located in Chardon, Ohio, is a reputable company specializing in ceramic manufacturing. With over four decades of experience, GBSA has established itself as a trusted provider of high-quality alumina ceramic components. The company's dedication to delivering durable, corrosion-resistant, wear-resistant, and thermally shock-resistant ceramic parts has made them a preferred choice for clients across various industries. GBSA Inc. offers a comprehensive range of alumina ceramic components designed to withstand harsh conditions and provide superior performance. The company's product portfolio includes alumina ceramic components that find applications in furnace processes, thermocouple protection tubes, sandblasting and welding nozzles, fuel cell and laser parts, bushings, mechanical seals, and various other industrial processes. Clients can rely on GBSA to provide them with alumina ceramic components that can withstand corrosion, wear, and thermal shock, providing advantages in a wide range of applications. In addition to their exceptional products, GBSA Inc. provides a range of services to meet the unique requirements of its customers. The company collaborates closely with clients to understand their specific needs and requirements. GBSA's experienced team of engineers and technicians works diligently to develop customized ceramic solutions that meet the highest quality standards and precise specifications. The company also offers prototyping services to validate designs before full-scale production. Advanced techniques and equipment are utilized to create accurate prototypes, which undergo rigorous testing to ensure their performance and durability under demanding conditions. GBSA Inc. possesses advanced ceramic manufacturing capabilities that set them apart in the industry. The company specializes in alumina ceramics and has extensive knowledge and expertise in working with this material. Their skilled workforce understands the unique properties and characteristics of alumina ceramics, allowing them to develop components that excel in demanding environments. GBSA's team of engineers and designers leverages their expertise to develop custom alumina ceramic components that meet the specific requirements of clients. They provide guidance on material selection, component design, and manufacturing processes to ensure optimal performance and efficiency. GBSA maintains stringent quality control measures throughout the manufacturing process. The company's commitment to quality ensures that each alumina ceramic component meets or exceeds industry standards, offering reliability and longevity in their applications. GBSA's alumina ceramic components find applications across various industries, including furnace processes, thermocouple protection, sandblasting and welding, fuel cells, lasers, bushings, mechanical seals, and more. The versatility and durability of these components make them suitable for challenging environments and demanding applications.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services