Blasch Precision Ceramics

Blasch Precision CeramicsRequest A Quote

Albany, NY | 518-436-1263https://www.blaschceramics.com/

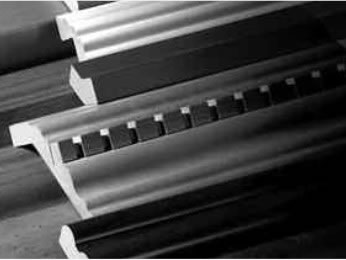

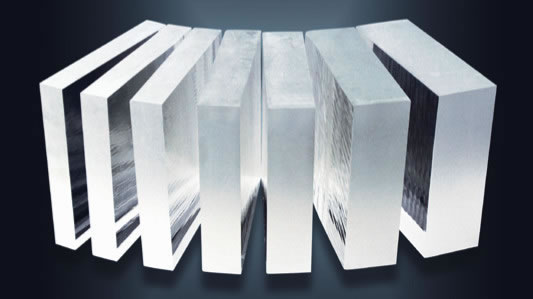

Blasch Precision Ceramics is a leading manufacturer of advanced ceramic components, offering customized solutions to meet the demanding requirements of various industries. Founded in 1979 and headquartered in Albany, New York, USA, the company has a global presence, serving customers in North America, Europe, Asia, and the Middle East. Blasch's expertise in ceramic manufacturing allows them to provide tailored solutions for a variety of applications, including chemical processing, mining, power generation, and petrochemical industries. Their ceramic products offer excellent resistance to wear, corrosion, and thermal shock, making them ideal for harsh operating environments. One of Blasch's primary strengths is their ability to develop and produce complex ceramic shapes and components that meet specific customer requirements. They work closely with their customers to understand their needs and provide innovative solutions to their challenges. Blasch has extensive research and development capabilities, and their state-of-the-art facilities allow them to design and test new materials and products quickly. Blasch's product portfolio includes advanced ceramics, specialty ceramics, and silicon carbide products. Their advanced ceramics offer exceptional mechanical properties, such as high strength and wear resistance, and are used in demanding applications where performance and reliability are critical. Their specialty ceramics provide outstanding chemical resistance, thermal shock resistance, and erosion resistance, and are used in applications such as chemical processing, mining, and power generation. Blasch's silicon carbide products offer excellent thermal conductivity and thermal shock resistance, making them ideal for high-temperature applications. Blasch also offers a range of services to complement their ceramic products, including design and engineering, materials testing, prototyping, and manufacturing. Their design and engineering services help customers to optimize their ceramic components for performance, durability, and cost-effectiveness. Their materials testing services provide accurate and reliable data on the properties of ceramic materials, allowing customers to make informed decisions about material selection. Blasch's prototyping services enable customers to test and refine their designs before committing to full-scale production. And their manufacturing services ensure that ceramic components are produced to the highest quality standards, with tight tolerances and excellent repeatability. In conclusion, Blasch Precision Ceramics is a reputable company with a strong track record in the manufacturing of advanced ceramic components. Their expertise, state-of-the-art facilities, and commitment to customer service enable them to provide customized solutions for various applications across different industries. They continue to invest in research and development to stay at the forefront of ceramic technology and offer innovative solutions to their customers.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services